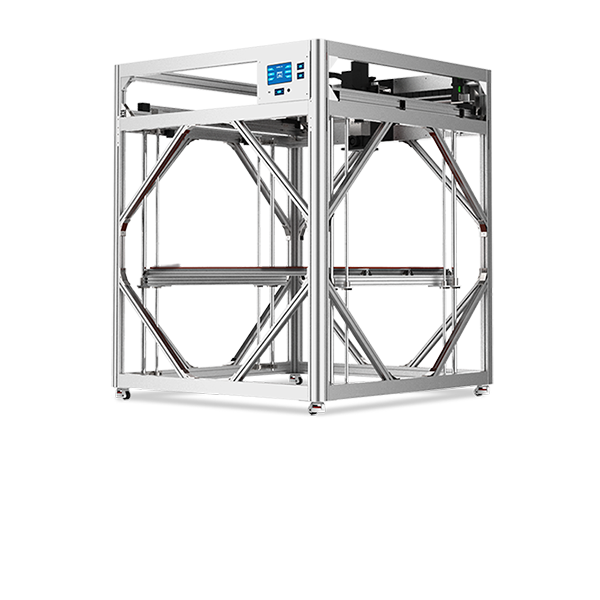

Complete your workflow quickly and easily with Dowell's industrial pellet 3d printer.

1 2 3 4 5 6

1 2 3 4 5 6

Feature:Faster Print Speed

Advantage: Improved printing speed and increased throughput

Benefit: Time saving

Feature: Cheaper materials

Advantage: Pellet costs 65% - 80% less than filament of the same plastic

Benefit: Cost saving

Feature: Larger Print Sizes

Advantage: 1600*2400*1600mm large format printing size

Benefit: One-time molding to improve durability

Feature: Versatility

Advantage: Various materials are available, old materials can be reused.

Benefit: Reduce costs, expand choices

Feature: Flexibility

Advantage: Custom for enclosure, system, temperature, and more.

Benefit: Meet various requirements

Feature: Professional

Advantage: 3-stage temperature control , screw extrusion, industrial-grade configuration.

Benefit: Ensure high quality output

Designers from Japan bring new possibilities for replacing final components, achieving mass customization and producing high-performance components.

The development of art is inseparable from technological progress, and technological progress also promotes the development of art. New Zealand designers use our printers to combine 3D printing with sculptural art to create stunning works of art.

The advantage of 3D printing technology is that it can customize your ideal products, so it is not difficult to imagine that 3D printing technology will be used to design more unique furniture in the future.

Traditional manufacturing methods may not be able to meet the requirements of geometrically shaped industrial accessories, but 3D printing technology can easily manufacture complex internal structures and structural components that integrate multiple parts.

Years of

Experience

Dowell 3D has been dedicated to creating versatile, adaptable, and economical industrial 3D printing solutions for customers since 2014.

Our services include designing and producing FDM 3D printers,FGF 3D Printer,certifying and testing advanced materials, and improving software to ensure complete control over the quality and performance of our technology.

Dowell 3D's skilled engineers create solutions using cutting-edge materials to manufacture prototypes and end-use parts. We are committed to providing comprehensive and responsive service to our customers.

Our technical team is ready to address any technical, customization or service-related requests to assist manufacturers in bringing innovative ideas and products to market rapidly.

R&D Experience

Professional technician

Workshop area

Cooperative customers