Home / Products / FDM 3D PRINTER / DM Series

Specification

|

Model |

DM Series |

|

Frame |

40mm aluminum section |

|

Printing bed |

6mm tempered glass |

|

Nozzle diameter |

0.4/0.6/0.8/1.0mm |

|

Nozzle temperature |

0-420℃ |

|

Bed temperature |

0-100℃ |

|

Location accuracy |

0.02mm |

|

Layer height accuracy |

0.04-0.6mm |

|

Extrusion flow rate |

Max 18mm³/s,80g/hour |

|

Operation firmware |

R&D Based On Klipper |

|

Operation interface |

7'' full color touch screen |

|

File format |

STL/OBJ/GCODE/JPG |

|

Filament available |

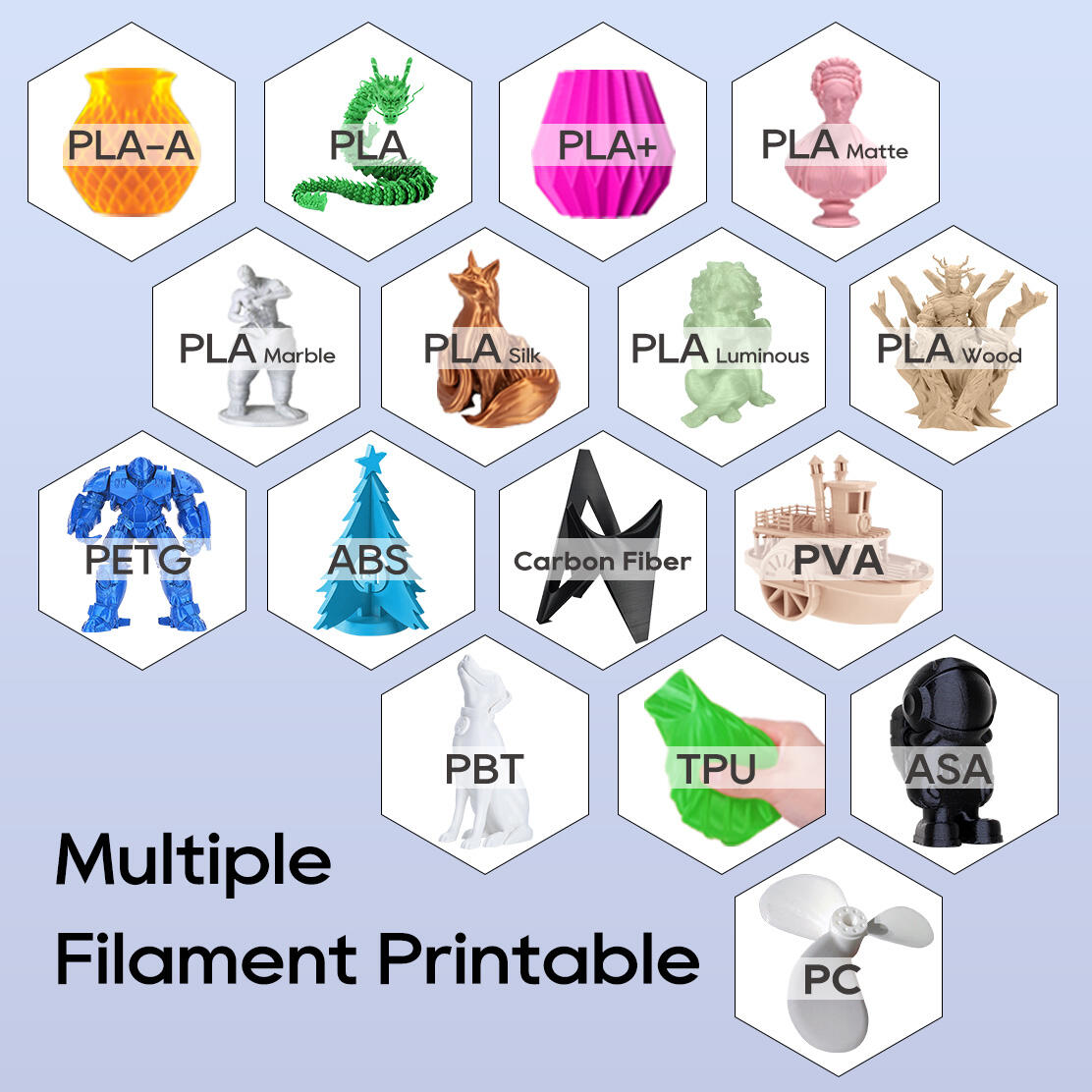

1.75mm PLA,PETG,ASA,ABS,PVA,TPU,WOOD,CARBON FIBER,etc. |

|

Connection |

SD Card/U Disk/WIFI |

|

Input power |

110/220V |

|

X&Y axis |

High precision linear rail |

|

Basic functions |

*Auto leveling *Filament sensor *Remote control *Wifi connection *Visible Printing status *Visible temperature graph *Installable external camera *Configuration editable *Z-offset adjustment *Speed & extrusion & cooling adjustment *Gcode viewer *History record *Emergency stop button |

|

Optional |

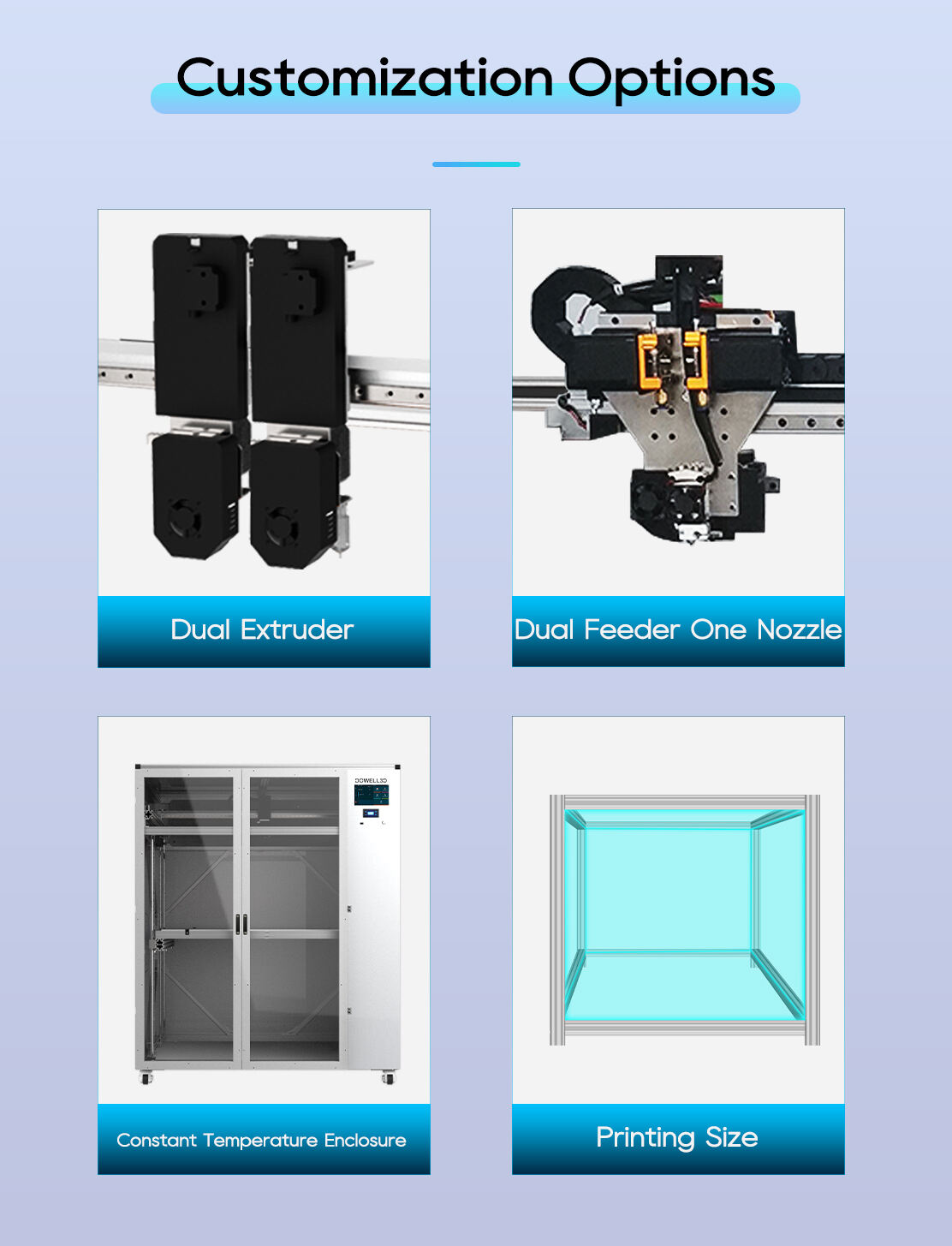

*Dual feeder one nozzle *60℃ Enclosure *Dual extruder *Customize printing size |

User's Feedback

Product Description

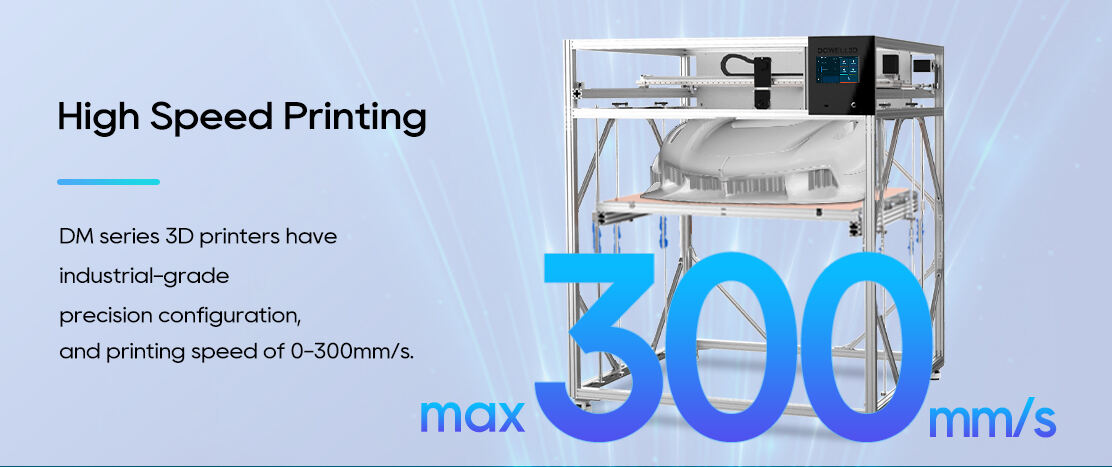

Dowell industrial 3D printer DM series has industrial-grade precision configuration and the most advanced technology, which can ensure high-quality output at high speed.

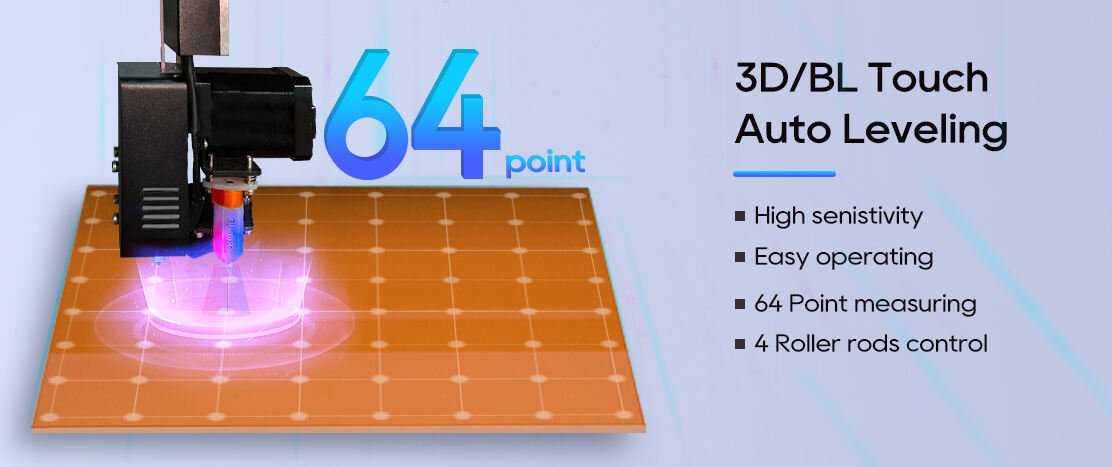

First, the 4 corners are detected, and then the 8*8, 64 points rectangular detection of the flatness of the bed is carried out. It adjusts the inclination by rotating the screw and automatically compensates for unevenness to ensure perfect flatness before each printing job.

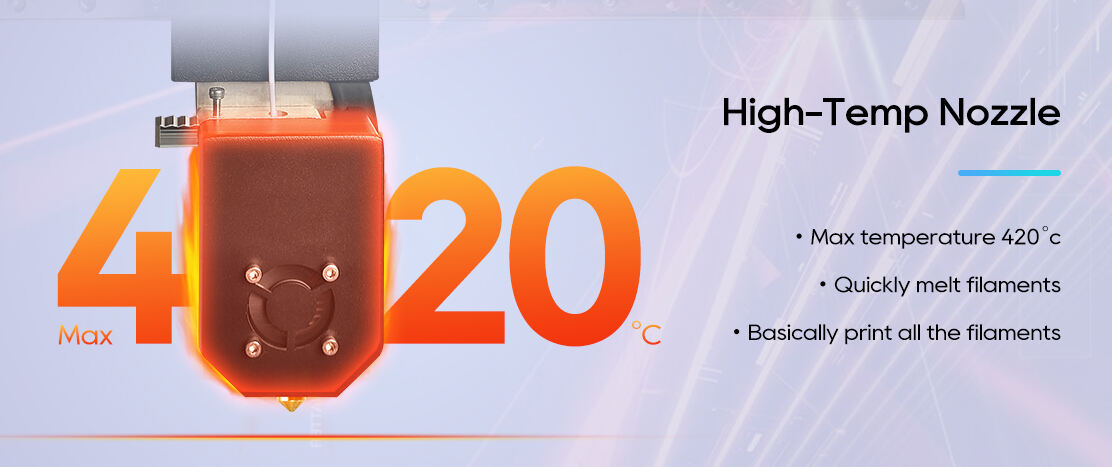

Dowell extruder features a dual drive gear system and metal heating block for enhanced heat transfer and high temperature compatibility. It uses thermal insulation and an upgraded temperature sensor to support printing temperatures up to 420°C.

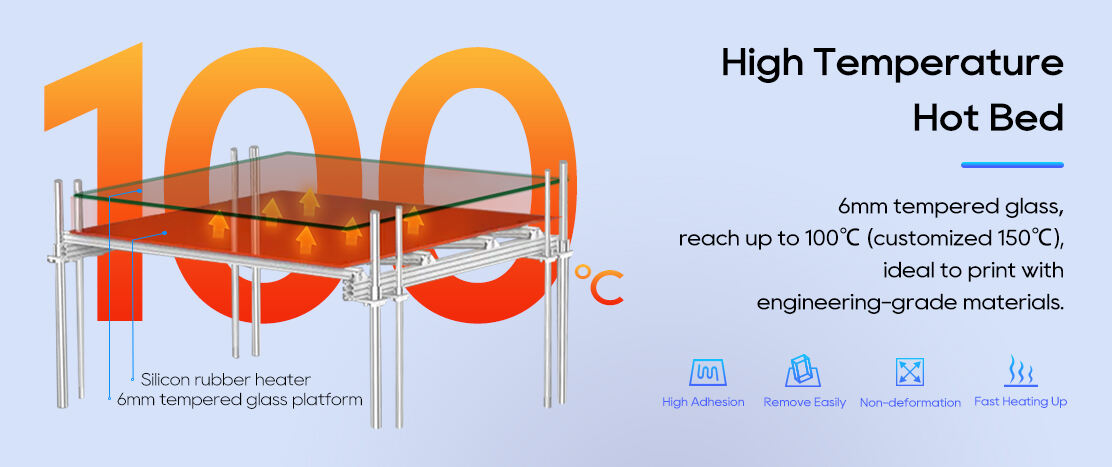

DM series machine standard configuration big wattage heating bed, motherboard temp-control which is accurate and fast, it can reach 100/150℃. Tempered platform can bear more than hundreds kilogram, safe and secure.

High precision, small friction resistance, running unimpeded, to ensure the accuracy and stability of the machine.

First, the 4 corners are detected, and then the 8*8 points rectangular detection of the flatness of the bed is carried out. It adjusts the inclination by rotating the screw and automatically compensates for unevenness to ensure perfect flatness before each printing job.

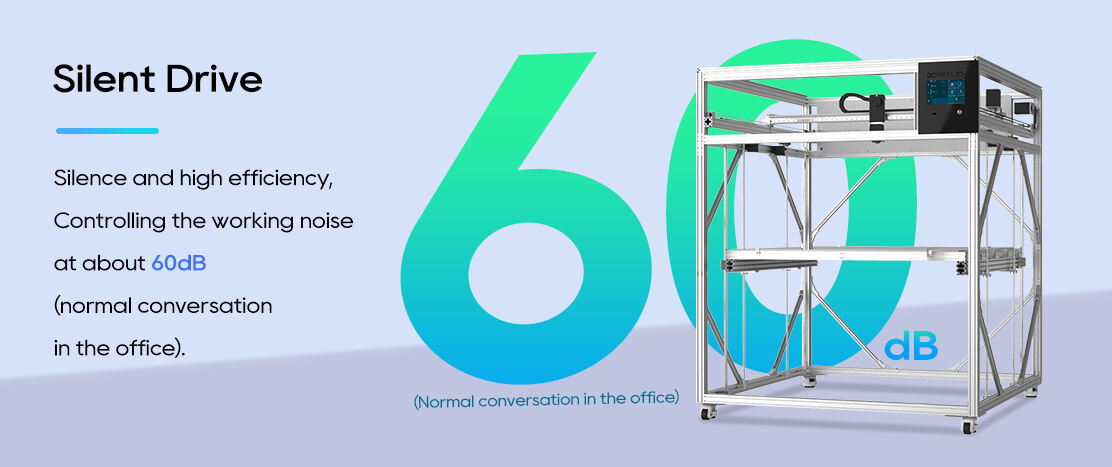

At the same time with silent and efficient two advantages, effectively reduce work noise.

DOWELL 3D printer is equipped with remote maintenance modules to analyze possible anomalies and to reduce the possibility of downtime for the advantage of productivity. The remote management feature includes sending software updates to allow the DOWELL 3D Printer to evolve over time, acquiring new features, parameters, and intelligence.

Dowell3D independently developed 420° high temperature nozzle with constant temperature enclosure can print a variety of filament perfectly.

Customization options

In addition to its fundamental features, DOWELL 3D printers are also equipped with customizable functionalities, allowing users to tailor the printer to their specific needs.

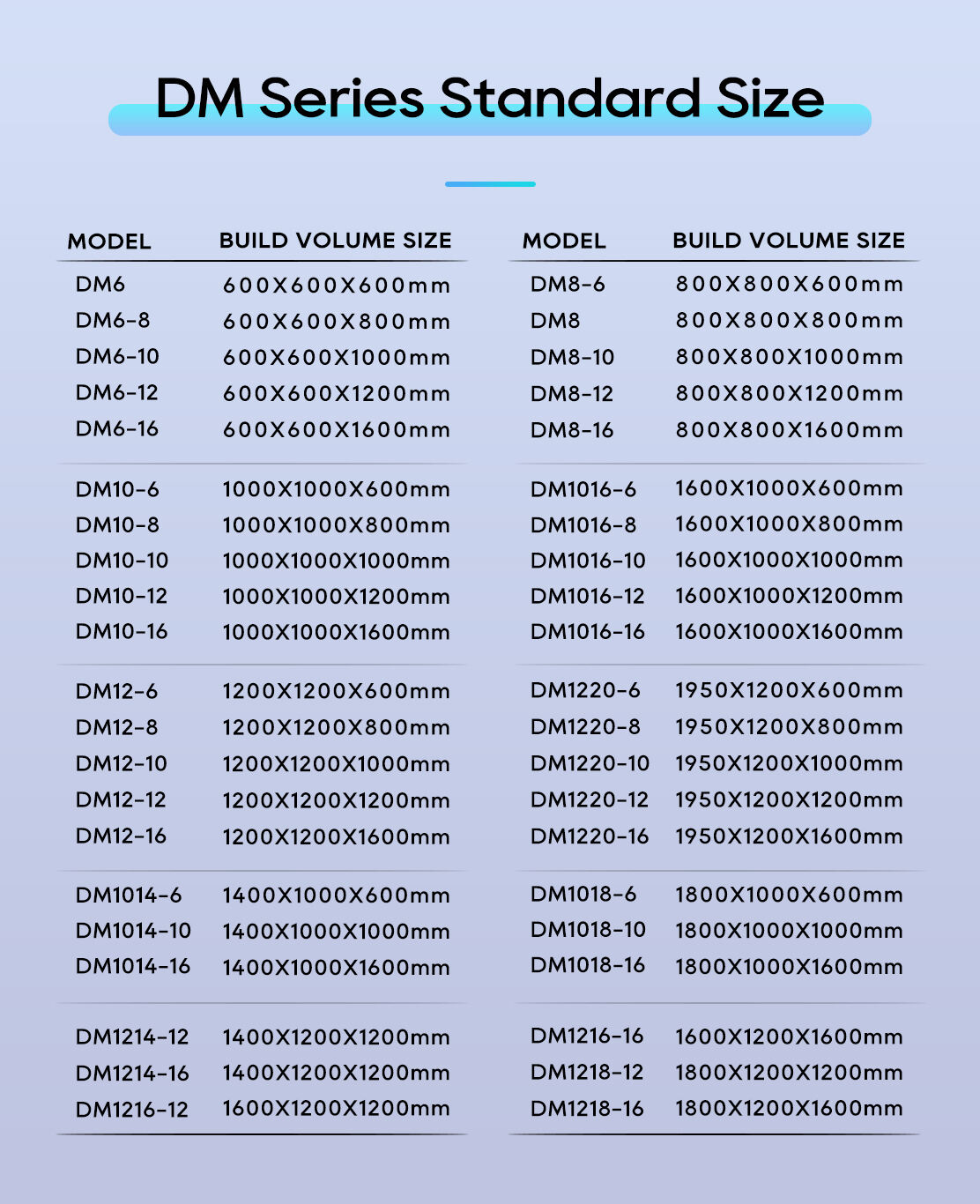

Extensive Printer Size Options

In addition to these sizes, you can contact us for customized dimensions tailored to your specific requirements.

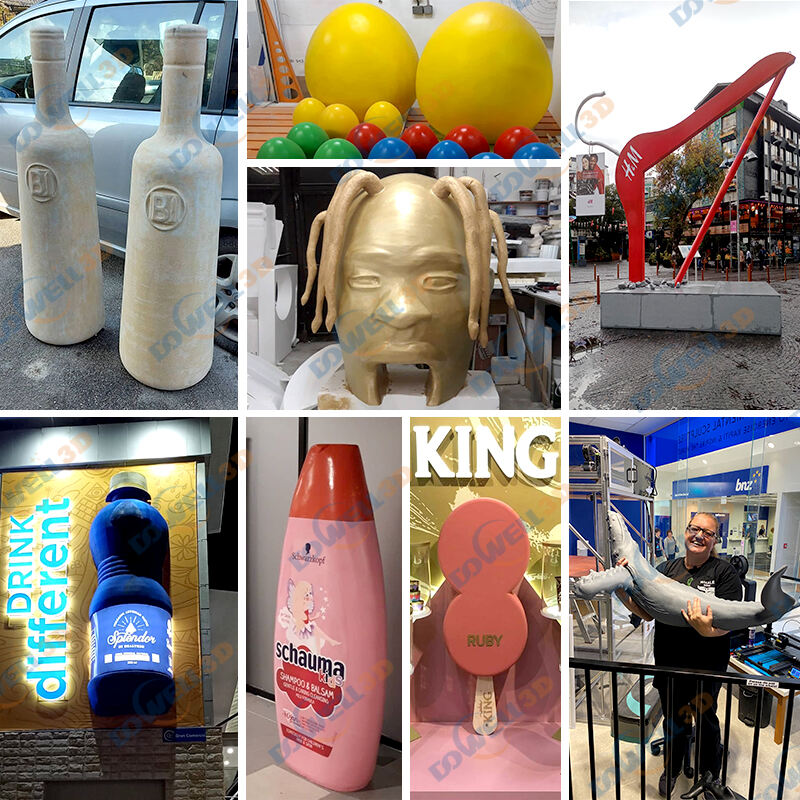

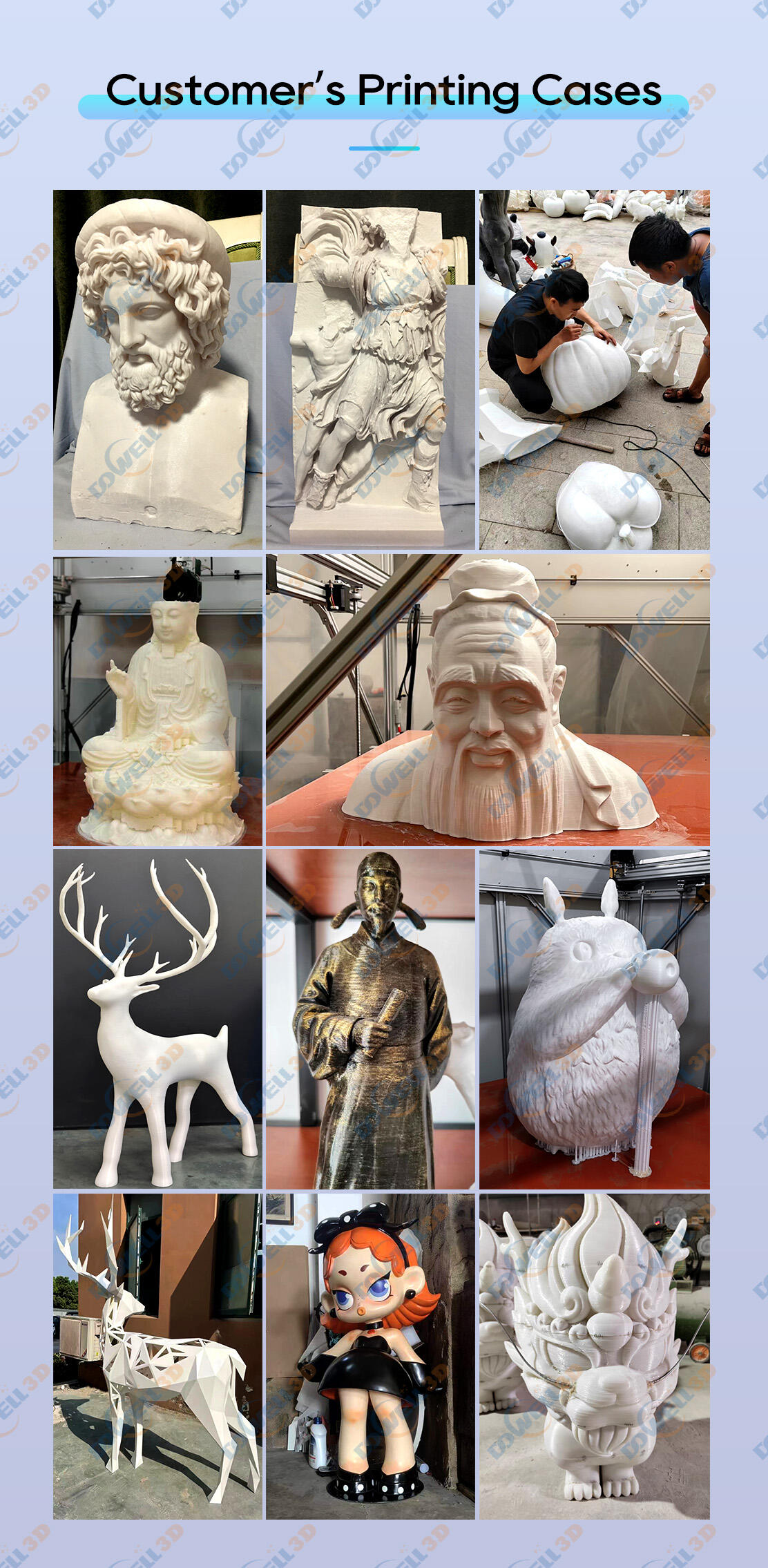

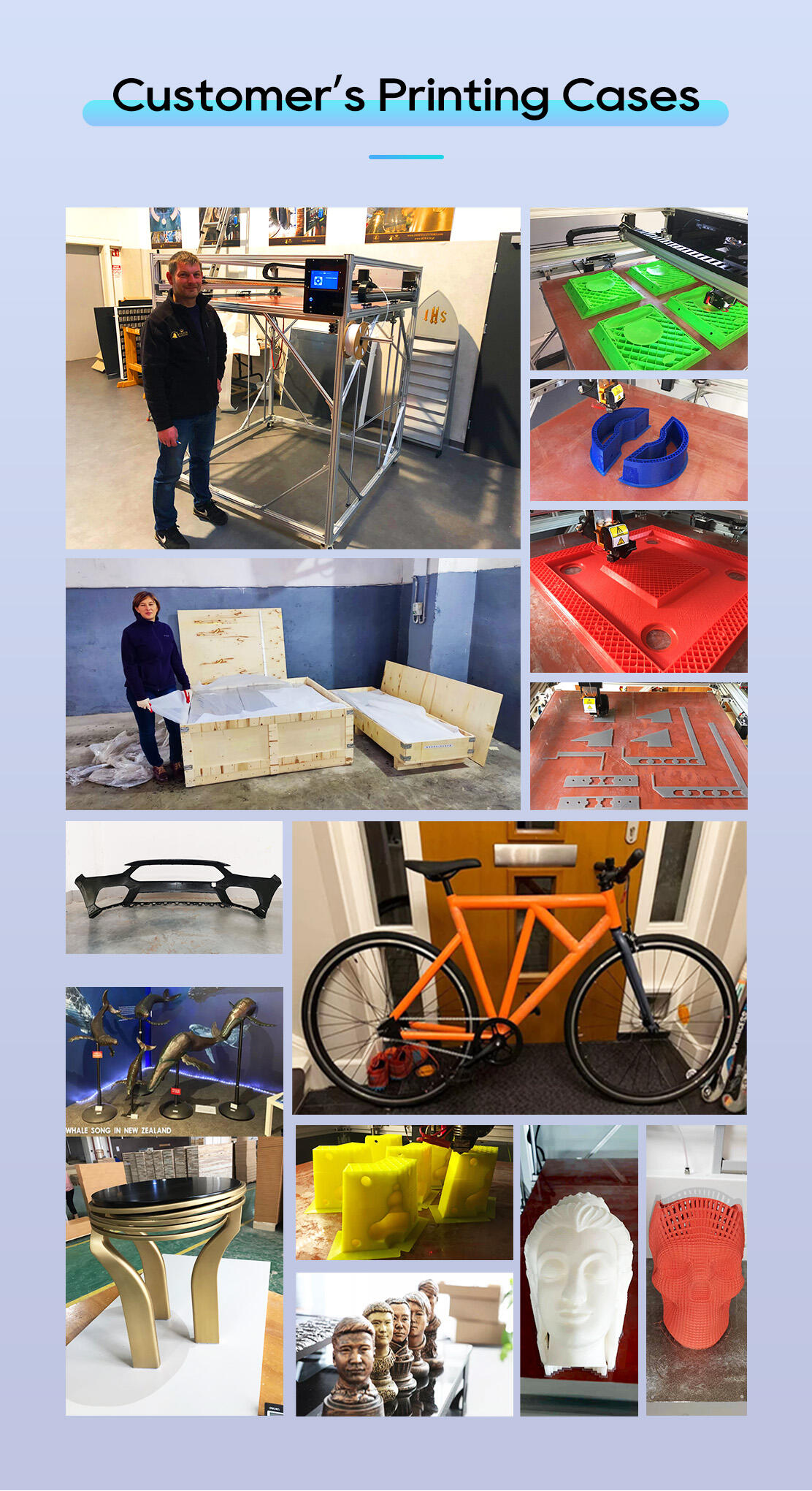

Customer's Printing Cases

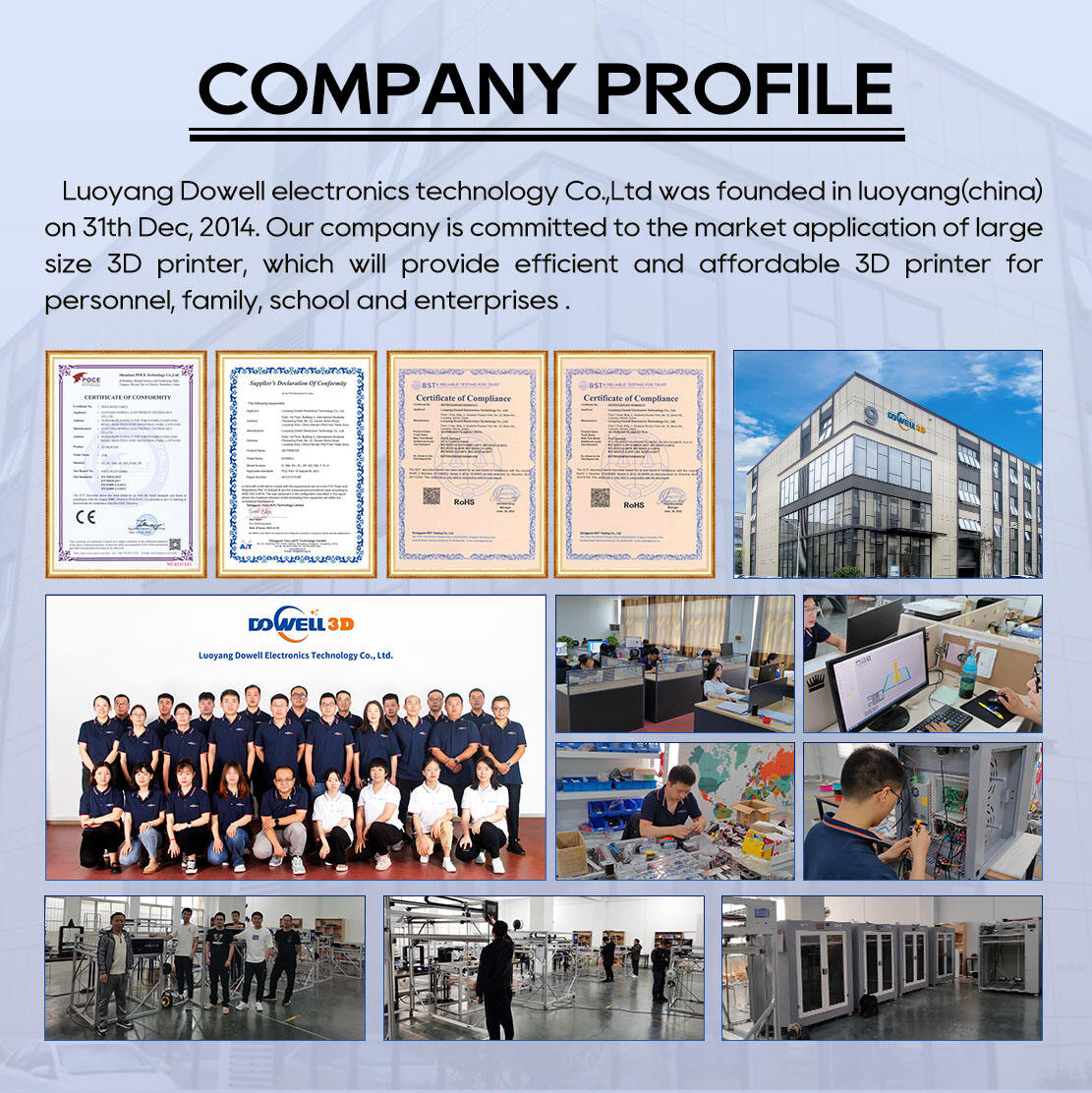

Company Profile

FAQ

1-Are you a factory?

Yes, we are a directly manufacturer focus on developing and produce large industrial 3d printers.

2-Payment method

Negotiable.

3-Shipping method

DHL, UPS, Fedex, TNT, sea shipping, air freight, by train.

4-What's your lead time?

If the product you order is our standard model, lead time is around 14 days; or else lead time is negotiable.

5-How do you guarantee the quality of the printer?

We have 100% tests before shipment. We will supply photos and video of tests before shipment. We can guarantee that our 3D printer will have absolutely no quality problems before shipment. Then we will arrange the shipping under the confirming.