3D printers are disrupting the way we do things, and that definitely includes car parts! Using a 3D printer, businesses can produce car parts faster and more cheaply as before. This new method of producing things is especially valuable for businesses that are dealing with cars because it saves them time and money. Here, we’ll take a closer look at the ways 3D printing is changing the automotive industry in a big way.</p>

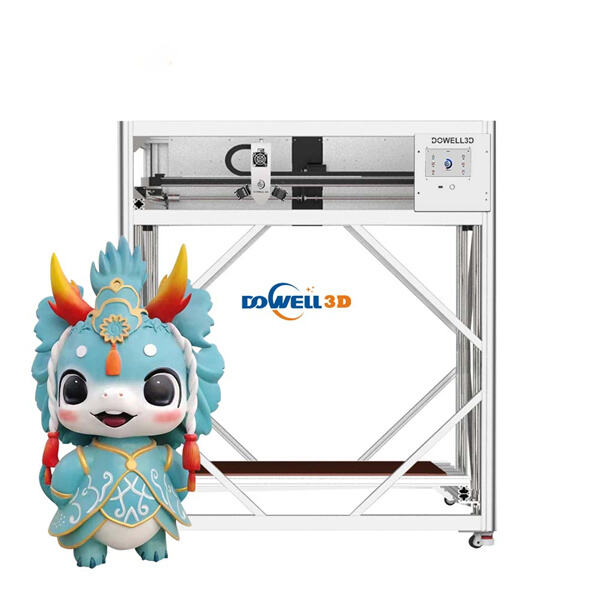

At Dowell 3D, we provide innovative 3D printing services that can revolutionise the way you produce car components. It speeds up the process by 3D printing the filaments instead of using expensive, slow methods of the past. In other words, you can produce parts faster, and react more quickly to whatever your customers happen to want. It’s the difference between finding and making a special part for a car immediately rather than waiting for it to arrive from somewhere else.</p>

Precision One of the most significant results of 3D printing for the automotive industry is the precision it provides. When you 3D print parts they fit perfectly, the printer is replicating the design exactly. That lowers the potential for errors, which could be expensive and take time to correct. You can have confidence that every part you print with the Dowell 3D Printers is in high quality.</p>

Check out our FDM 3D PRINTER for high-quality 3D printing results.

It’s a car business thing: Everybody wants to be the best. To do that, you need the best technology. Dowell 3D printers helps you to manufactures high-quality strong and long lasting car parts. This is great news, as it means your products are going to be unique in the market. You will have a better product and the customer will see it and select your parts rather than others.</p>

The other main benefit of 3D-printing is the cost and time it saves. There can be a lot of machines and people involved in traditional ways of making car parts, and that tends to add up. 3D printing allows you to make parts with only one machine and fewer people; it saves a lot of money.” And, you can produce parts far more quickly, so you can sell them sooner.</p>

Learn more about our 3D MATERIAL options for efficient and cost-effective 3D printing.

Finally, 3D printing allows you to be more artistic. You can design parts and make them that you couldn’t make before. This can open up exciting new possibilities in how we make cars better — and more fun. You can customize parts to suit particular needs with Dowell 3D printers, and this is a very popular feature with our customer base.</p>

Dowell's 3d printer for automotive and manufacturing centers houses six series products and more 100 different types of models products, as well as 300 types spares parts. This enables Dowell to meet requirements of its clients. Dowell has been awarded numerous internationals patents and certifications.

Dowell's 3d printer for automotive, universities as well as technology-related companies. Dowell serves more s20,000 customers across globe, and exports to more 60 nations, offering security and reliability logistics to ensures that each items gets each customers fully and quickly.

The principals activity of the firms 3d printer for automotive, as well as 3D materials. Our current products includes FDM plastics filament 3D printers, FGF 3D printers made plastic particles, and 3D materials, which includes PLA, PETG, ABS TPU, Carbon Fiber glass fiber, PP, and other composites materials.

The company is certified CE, SGS, 3d printer for automotive and other certifications. It has more than 40 patents and is protected by independents intellectual property rights and is recognized as an "Luoyang High-Tech Enterprise". Before leaving the factory, every products undergoes a rigorous tests and a reports is issued.