Wholesale buyers can take advantage of Dowell 3D as an affordable option for additives to be used with 3D printer pellets. Manufacturers can reduce their material costs & lead times with custom orders for bulk quantities of pellets made to order. This technique incorporates the flexibility to choose materials and also provides for customization to serve the countless applications of different sectors. With everything from ABS, PLA, PETG and available in pellet form through our store, bulk buyers can rest assured that we have the materials to match their production.

A huge benefit of using 3D printer pellets is all the money you’re saving by purchasing materials in bulk. As wholesale customers are buying pellets and not filament spools, they can save bulk on material costs. This affordable option enables producers to use their money in other important parts of their business. 3D printer pellets also provide a higher degree of customization and material choice, so manufacturers will be able to accommodate some of the most specialized operations without sacrificing quality.

Incorporating 3D printer pellets into your production chain can provide numerous advantages in terms of productivity and part quality. Material blend definition and full range of color options provide the additional versatility needed for product development to support unique prototypes and end-use parts. Plastics processors also can minimize material waste and maximize material use via the use of a pellet, for more sustainable and economical production processes. Manufacturers no longer have to compromise: by leveraging Dowell 3D’s technology and materials, they can save time on the workflow and shorten lead times without sacrificing quality.

Along with the ever-changing landscape of modern manufacturing, 3D printer pellets have become a preferred option for professionals in the industry. Pellets are suitable as a inexpensive feedstock and for use in rapid prototyping, which makes them an interesting alternative in additive manufacturing. Manufacturers can stay ahead of competition, push innovation and respond to the increasing ADVERTISEMENTdemand for personalisation in vertical markets by embracing this trend. The switch to 3D printing pellets is a progressive method in today’s manufacturing, where businesses can take advantage of the latest technology to create sustainable products.

At Dowell 3D, we pride ourselves on the quality and innovation of our line of 3D printer filament pellets. Our pellets are developed and tested to increase the performance of a variety of applications. Material Homogeneity and Accuracy Ensured Naturewing pellets provide the best result in comparison with others for any industrial project. What's more, our team of experts brings decades of experience to troubleshooting and implementing bespoke solutions to help manufacturers confidently drive toward their manufacturing goals.

3D printer pellets are raw form material which can be melted and extruded in a 3D printing process instead of purchasing filament spools for the purpose, providing more choice, flexibility and potential cost saving than commercial filament spools.

Dowell 3D will provide the premium materials consulting for Wohlers Associates and service of software optimization and customization to help 3D printer pellet manufacturers get the most out of their projects.

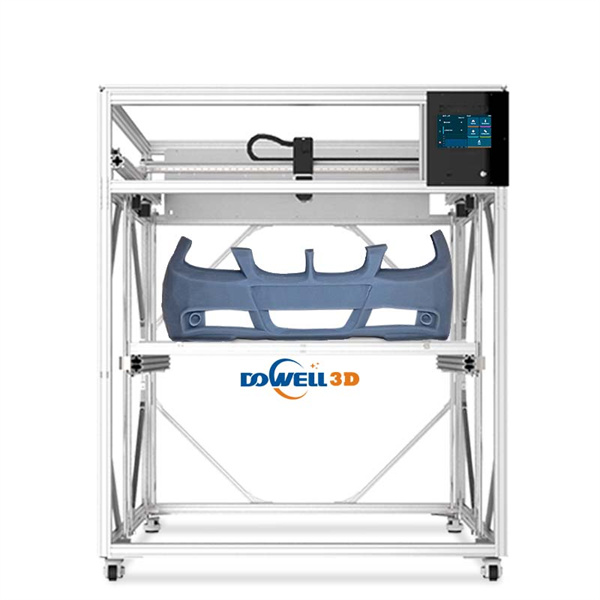

The company's main business 3d printer pellet and 3D materials. Our primary products FDM plastics filament printers as well as FGF plastic particles 3D printers. 3D materials includes PLA, PETG ABS, TPU, Glass Fiber, Carbon Fiber, PP, and other composites materials.

Dowell's 3d printer pellet and R and D centers six series and more than 100 distinct designs products, as well as 300 types of spares parts. This allows Dowell meets the requirements of its clients. Dowell received numerous patents as well as internationals certifications.

Dowell's clients mostly universities, research institutions and businesses that are technology-based. More than 3d printer pellet, and they exports products to more than 60 nations. They offers safe and reliable logistics in orders ensure that every products gets to its purchaser in complete and in full.

The company is certified CE, SGS, 3d printer pellet and other certifications. It has more than 40 patents and is protected by independents intellectual property rights and is recognized as an "Luoyang High-Tech Enterprise". Before leaving the factory, every products undergoes a rigorous tests and a reports is issued.