Ever wonder how they make car bumpers? And it’s made possible by high-tech machines such as the Dowell 3D car bumper machine. The machines are built to produce accurate bumpers fast and effective and in premium quality. Now we are going to look into the world of car bumper machine and how it benefits the automotive industry.

The Dowell 3D car bumper molding machine is a new ball game. It can spawn bumpers faster than the game itself. Genuine and Original is used with the most recent programming to ensure perfect results. It warms plastic, shapes it into a bumper shape, and quickly cools it. Their technique is fast and ensures that bumpers are strong and fit the cars properly.

Quality is number one as far as car bumpers are concerned. Dowell 3D machines are meticulously designed to make sure that each bumper they produce is of high quality. Not only are these bumpers tough, they look great on the car too. Car manufacturers can rely on Dowell 3D machines to produce bumpers that meet their high standards and that will keep the end customer satisfied.

Dowell 3D bumper machines enable factories to be more orderly. The entire bumpers manufacturing gets easier and faster with these machines in use. Factories don’t need to employ as many tools or steps, which saves time and lowers the possibility of errors. This is part of the recipe for how factories get better and make more bumpers in less time.”

Car bumpers are expensive to manufacture, but Dowell 3D machines can cut costs. These machines move quickly and minimize material waste (the press has a 6-percent waste factor, while the 3-D printer wastes at least 20 percent of its material.) Bumpers help factories make more bumpers affordably, without wasting materials or working to correct mistakes. That makes Dowell 3D machines so clever in that you save on the cost and still produce good bumpers.

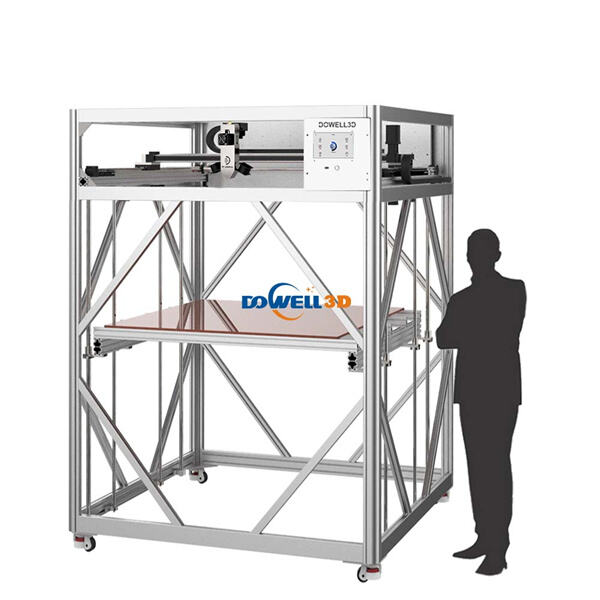

Dowell's car bumper machine and R and D centers six series and more than 100 distinct designs products, as well as 300 types of spares parts. This allows Dowell meets the requirements of its clients. Dowell received numerous patents as well as internationals certifications.

The business is protected under intellectual property rights and has been awarded independent certificates from SGS, FCC, CE and many more. It has car bumper machine. Before leaving the factory, every product is tested thoroughly and a report is issued.

Dowell's principal customers are research institutes, universities and car bumper machine. They serves more 20,000 customers around the globe and exports to more than 60 countries. They provides the most reliable and secured logistics ensure that each products will reach every client completely and efficiently.

The car bumper machine is FDM/FGF printers as well 3D materials. Our most popular products includes FDM plastic filament printers as well as FGF plastics particle 3D Printers. 3D Materials includes PETG, PLA ABS, TPU and Glass Fiber, Carbon Fiber, PP and other composites materials.