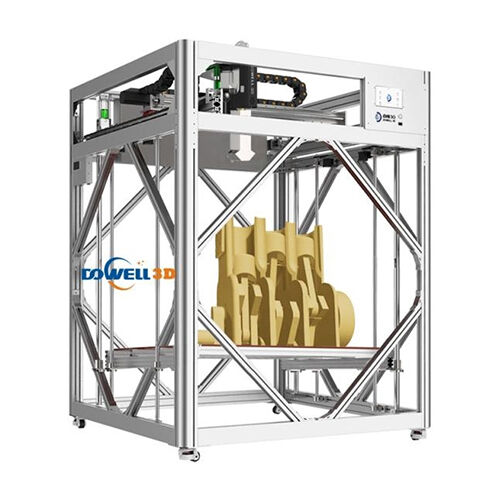

Production of giant parts in the mining, building and farming sectors has always been equated with complicated casting, huge machining and long assembly belts. These conventional techniques, although dependable, are usually limited by the design complexity, lead time and material efficiency. Massive-format industrial 3D printing is the solution is transforming this landscape today. At the Luoyang Dowell Electronics Technology Co, Ltd., we embrace the best of this transformation and we are creating high scale 3D printing systems that would allow manufacturers to overcome the traditional constraints and move into a new era of innovations.

Revisiting Design Freedom and Complexity

Conventional methods of fabrication have a devastating effect on the design that engineers are able to conceive. Larger geometries, internal lattices of lightweighting, embedded coolant channels are typically inaccessible or prohibitively costly to do with traditional tools. The barriers are eliminated by large 3D printers. They are made by adding layers of components in one way or another based on the digital models, and they allow making highly optimized monolithic structures. This implies that engineers can develop to ultimate performance and weight saving without being tied by manufacturing reality. The outcome is the generation of more powerful, light and efficient heavy equipment components than ever before. This is because it is able to consolidate parts, as assemblies of dozens of parts can be made into one strong printed part, which completely simplifies supply chains and the assembly process.

Increasing the speed of Prototyping and manufacturing

Time is an important resource in the manufacture of heavy equipment. The development stage of a new bucket, blade or housing can require months to be developed with conventional patterns and molds. Massive 3D printing shows great reduction in this ordering. A full-sized functional prototype can be developed within a few days and large-scale prototyping can therefore be done quickly and easily. This has been applied in prototyping all the way to tooling, fixtures and even finished parts of low volume or specialised machinery. With development cycles greatly reduced, manufacturers can deliver new products to the market more quickly and react to the unique needs of clients, or repair needs in the field, more quickly, securing a significant competitive edge.

Increasing Sustainability and Material efficacy

Traditional machining can be quite wasteful of material, particularly where using high-cost high-strength alloys, due to the inherently subtractive nature of machining. Big-volume 3D printing is an additive process in nature. It places the material in the required areas only and this reduces wastage and results in more responsible manufacturing. This effectiveness then translates to cost saving on raw materials. Also, manufacturing lightweight but strong components has also helped in enhancing the overall energy efficiency of the end heavy equipment which lowers fuel usage and environmental impact throughout the life span of the machine. This is in keeping with the increasing industry concern on sustainable and responsible manufacturing.

The Future of Digital Warehousing and On-Demand

The principle of holding the huge physical stocks of spares is logistical and financial strain on the heavy equipment industry. The large 3D printers open the possibility of digital warehousing. Manufacturers have the option of storing digital part files in lieu of stocking not used, yet, critical components. In the case of a requirement of a part, be it of an older model or of an emergency repair, it can be 3D printed on-demand, locally or at a distributed service center. This transforms supply chain logistics and lowers inventory expenses, as well as virtually eliminates downtime by customers who have to wait a part to be shipped as far away as a distant warehouse, guarantees maximum operational availability.

The mission of the Luoyang Dowell Electronics Technology Co, Ltd. is to avail the industrial appliances that can enable this future. We are devoted to our strong engineering and modern state printing technology in order to provide us with the reliable solutions of large-scale production. It is our opinion that the heavy equipment industry can create not only larger, but smarter, more efficient, and more resilient equipment through the power of big 3D printing in the future.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

BE

BE

HY

HY

KA

KA

LO

LO

LA

LA

MN

MN

NE

NE

SO

SO

MY

MY

KK

KK

UZ

UZ