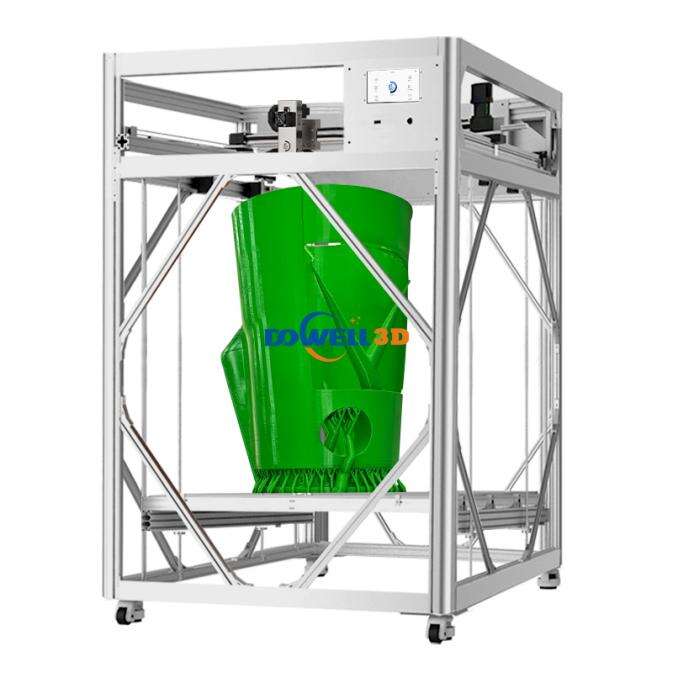

There is a radical shift in the manufacturing environment as there is the requirement of being more personal, pro-type quicker and require production. The first to jump the bandwagon is the big-format 3D printers whose usage is pushing the boundaries of custom manufacturing to the extreme. The development and integration of these modernized systems in the case of the innovative companies like Luoyang Dowell Electronics Technology Co, Ltd. cannot help but be preoccupied not only with the larger machines, but with a whole new world of innovative and industrial possibilities. These printers are also solving these unresolved nagging problems and broadening the range of applications previously considered too difficult or too costly to apply increasing the size of the printable workspace.

A Size Barrier assault within the Custom Manufacturing

The physical size of the print chamber of the printer has traditionally been the limiting factor on the size of custom parts that can be printed by 3D printing. This restriction meant that more intricate and bigger items had to be constructed out of multiple smaller items that would lead to the potential sources of weakness as well as, increased man power in the post-processing and design trades off. This critical deficiency is addressed by the 3D printers with large formats. They enable them to be fabricated in huge, advanced and completely incorporated components at a single process. The industries that are reliant on large and bespoke products are also changing: industrial equipment and full-size prototyping, architectural models and custom interior parts. The ability of its design and production of structures that could not be printed before is a revolution to designers and engineers.

Automation of Production and Time-to-Market

The installation of giant 3D printers strangles the production of the customized components on a large scale. The digital design to real object is so easy to accomplish and there is no expensive tooling or molding, or massive capacity installation in place that is usually involved in the manufacturing of large parts. This capability will help businesses to provide services to clients at a rate that has never occurred before. Prototypes can be done on a 1:1 basis, in that case they can be tested and verified and end products can be produced at the demand of the parts thus reducing the inventory needs. Considering that in the case of Luoyang Dowell, the company is specialised in strong and stable large format systems it means that the company will be providing the customers with a solution that would allow them to iterate faster, reduce risks that have been attributed to the development work, and potentially provide them with customised solutions that would enable them to launch more effectively than earlier.

Unleashing Design Freedom and Functional Integration

Besides the size, with large-format 3D printing, unlimited design freedom can be achieved. Modern generative designs or complicated lattice forms can no longer restrict engineers to the traditional manufacturing geometries and can optimize the structures in terms of weight, strength and material efficiency. This freedom allows the combination of what would be a number of many things into a single and powerful one, as well as a printed element that is light. Besides, large printers facilitate easier production of either very complex, fabricated geometries that are often vital to niche applications in sectors like aerospace, automotive, and the green energy sector. This is enabled by having the capability of producing parts which are not only useful in regards to size but also in regards to high performance.

Enhancing Cost-Effectiveness for Low-Volume Custom Runs

In the case of classic manufacturing, the unit cost of a custom-made, huge part is often prohibitively high regarding the cost of tools and set-up. Large-format 3D printing disrupts this model of the economy. It makes the small volume of production and one time production batches economically feasible. There is no penalty of cost to complexity; a very complicated component does not cost any more to implement to be printed, than a simple block of the same bulk. This economic benefit enables custom, mass production to be ready in specialized projects, research and development and specialized markets. It facilitates business to offer actual customization without enormous minimum order orders that makes a business stagnate in innovation and responsiveness to customer needs.

The next stage of the evolution of digital manufacturing is the large-format 3D printing. It shatters the scales and prepares the way to customization, complexity and efficiency that industries can do things in new ways altogether. Luoyang Dowell Electronics Technology Co, Ltd. has faith in the continued advancement of this technology and they have the capability to provide very robust and precise platforms which would allow the businesses to avail these opportunities fully. These printers will continue to improve and they will certainly be the key to the future of the on-demand and customized production, and how we design, create and be innovative at the world.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

BE

BE

HY

HY

KA

KA

LO

LO

LA

LA

MN

MN

NE

NE

SO

SO

MY

MY

KK

KK

UZ

UZ