Industrial prototyping is in the midst of a paradigm shift. A new paradigm is coming whereby long lead times, excessive cost, and large material waste were used to characterize the process. The new direction of this transformation is the use of the large-format 3D printing technology. To progressive manufacturing companies and engineering organizations, it is not a novelty to invest in large-scale additive manufacturing as a strategic necessity to accelerate, innovate, and gain a competitive edge.

Increasing the Innovation Cycle in Concept to Reality

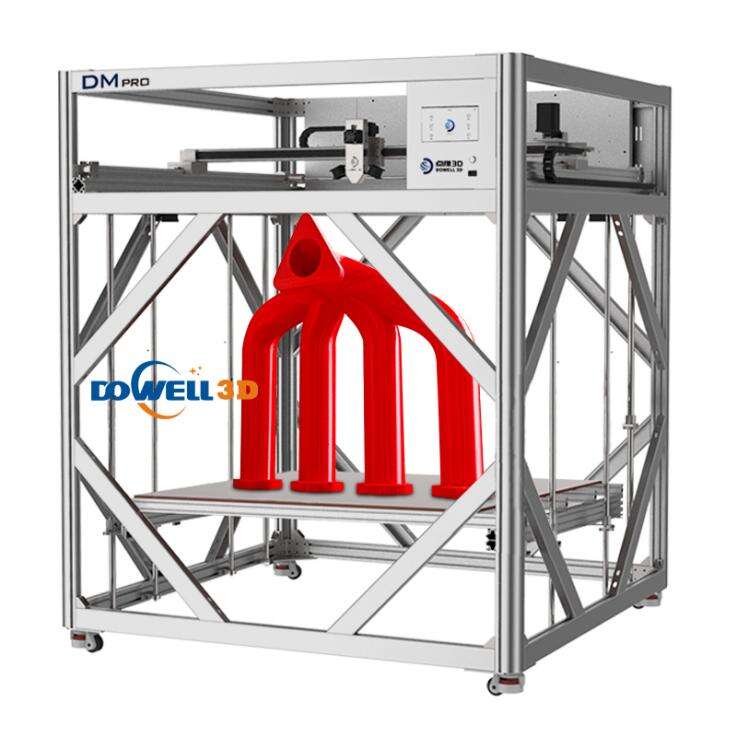

The most immediate effect of big 3D printers is the drastic reduction in the time scale of the product development process. Conventional prototype development of large industrial parts is usually based on complicated tooling, molds, or multi-assemblys which may take weeks or even years to develop. The process of 3D printing in large format eliminates these barriers. A full-size prototype of a large housing, a lighting effect or even a working component can be printed out, with one single large file, in only a few days. This will enable firms such as Luoyang Dowell Electronics Technology Co, Ltd. to enable our clients to go through quick iteration. Physical testing, evaluation, and polishing of their designs can now be done in real-time by the engineers and make faster decisions and also greatly reduce the critical path to a finalized and market ready product.

Breaking the shackles of Design Freedom and Integration

Other than speed, huge 3D printers release designers that are hindered by most traditional manufacturing. The technology makes it possible to create very sophisticated geometries, organic forms, and internal forms and structures that cannot, or are prohibitively expensive, to create with subtractive methods. This implies that prototypes are now capable of being real to the intended final design, the use of lightweight lattices, and assembly consolidation into one printed piece, and the optimization of functions and strength of shape. This is groundbreaking in the case of industrial prototyping. It enables the testing to be done not only of form, but of actual functional performance in the real world. Aerodynamics, fluid flow or structural integrity can be tested on a prototype that represents the advanced design of the final part and risk is minimized prior to investment of hard tooling.

Reducing Cost and improving Development Sustainability

The economic reason to use large-scale 3D printing in the field of prototyping is impressive. It removes the use of costly tooling that will only be used in the production of prototypes. This means greatly reduced initial expenditure particularly when the amount of volume in the case of low-volume or one-off prototype runs are already low. There is also a significant reduction in the amount of material waste, the process is additive in nature and it will only utilize the amount of material required to make the part. This is in line with the increased industrial concern on sustainable practices. Moreover, the capability to prototype at will means you do not have large stocks of parts physically, making logistics and storage easier. The resources saved can be used by the companies in more research, testing and innovation.

Collaborating to Secure the Future of Manufacturing

This future cannot be adopted by simply buying equipment but will need experience. It is at this crossroad of high technology and the real world that Luoyang Dowell Electronics Technology Co, Ltd. lies. Our field of interest is to offer solutions within the industry using the size and capability of large-format 3D printing to solve the problems of the real world. Our philosophy will enable clients to overcome the conventional constraints and experiment, and fail cheaply and quickly during the prototyping stage. This joint venture is a key to the full potential of additive manufacturing, which will revolutionize the way industries think, create and test the large-scale products of the future era.

The evidence is clear. Bigger 3D printers are essentially transforming the industrial prototyping business through the unparalleled speed, emancipation of design authority, as well as huge economies of scale. They are not just used as a means to develop models but a technology baseline to speed up innovation and develop a more dynamic, efficient, and creative future of manufacturing.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

BE

BE

HY

HY

KA

KA

LO

LO

LA

LA

MN

MN

NE

NE

SO

SO

MY

MY

KK

KK

UZ

UZ