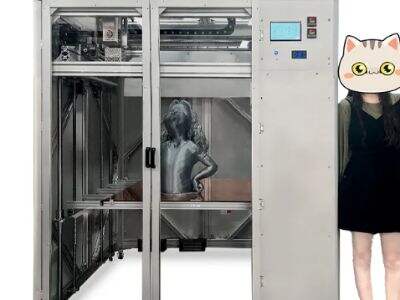

Carbon Fiber 3D Printing: Har du hørt om det? Det er en virkelig fantastisk teknologi, der opbygger ved at lægge lag af materiale på hinanden, ligesom Legos! Ved hjælp af denne metode kan du skabe forskellige slags objekter, herunder kreative design, der er svære at lave med nogle andre metoder. Men hvordan konkurrerer denne nye, moderne måde at lave ting mod de prøvede og sande metoder fra fortiden? Det gode, det onde, de ting du skal overveje for både Carbon Fiber 3D Printing og konventionel produktion. Så lad os gøre det dybere ind i det gode og det dårlige ved begge Carbon Fiber 3D Printing og traditionel produktion. Så lad os se, hvordan Dowell 3Ds Carbon Fiber 3D Printing klarer sig i denne sammenligning.

Fordele og ulemper ved Carbon Fiber 3D Printing

Måske det mest imponerende aspekt ved Carbon Fiber 3D-printning er, at den kan producerer ekstremt stærke, letvægtige 3D-printede objekter. Det betyder enkelt og klart, at genstande lavet med denne teknologi er robuste, men dog bæredele. Styrken kommer af dette specielle carbon fiber materiale, der gør dem varige i lang tid. Desuden, fordi ting laves ved at tilføje lag for lag, så kan man opbygge nogle meget komplekse former og design. Dette viser sig yderst nyttigt, når man vil lave noget, der ser fed ud eller har en underlig form, der ville være svær at fremstille ved hjælp af traditionelle produktionsmetoder.

Selvfølgelig har 3D-printning med karbonfiber også nogle ulemper. Hovedproblemet er, at det kan være meget dyrt at fremstille produkter med denne teknologi. Materialer og printning kan hurtigt føre til en høj pris. Og 3D-printning kan være langsommere end traditionelle produktionsmetoder. Grunden er, at printeren fungerer ved at langsomt bygge én lag ad gangen, hvilket kan tage lang tid, især for store opgaver.

Traditionel produktion vs 3D-printning

Nu skal vi gå videre og finde ud af nogle træk, der skiller traditionel produktion fra 3D-printning. Hvad er traditionel produktion og effektivitet. Den mest tangibele måde, hvorpå en enkelt person bruger denne sind-kropsteknologi, er ved at tage en mekanisk skærmaskine, såsom en sav, og skære et stykke metal i den ønskede form eller bruge en hammer og mejsel til at forme et stykke træ. Alle disse teknikker har været omkring i lang tid og er stadig mange gange den bedste måde at lave standardvarer på.

3D-printning fungerer imodtastede helt på en anden måde. Det bygger objekter én lag ad gangen. 3D-printeren bruger et egenudviklet materiale, såsom carbonfiber, og opvarmer det til dets smeltetemperatur. Materialet smeltes, og det smeltede materiale formes til den form, du ønsker. Denne proces gentages for hvert enkelt lag, indtil det færdige produkt er klar. Dette tilgangssåd er meget fleksibelt og giver stor plads til kreativitet i design.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

BE

BE

HY

HY

KA

KA

LO

LO

LA

LA

MN

MN

NE

NE

SO

SO

MY

MY

KK

KK

UZ

UZ