Jedan od ključeva za proizvodnju dosljedno visokokvalitetnog ispisa na stroju velikog formata je ovaj: da bi Z-os bio pravilno kalibriran i savršeno uravnotežen, mora biti apsolutno savršen. Nekonzistentan prvi sloj, vidljive linije slojeva, adhezija na granici, pomak i, u najgorem slučaju, potpuni neuspjeh ispisa nastaju kao lančana reakcija na nepravilno poravnanje ovdje. Činjenica da su ovi strojevi ogromni pojačava i najmanju grešku u kalibraciji, što čini preciznost poravnanja Z-osi toliko važnom da se ne može zanemariti. Dakle, evo kako to učiniti savršenim:

Zašto je kalibracija Z-osi kritična za velike formate:

Povećane greške: nekoliko milimetara nagiba ili zaključavanja je puno kada imate veliki volumen izrade.

Strukturni napon: široki okviri imaju tendenciju savijanja i širenja uslijed toplinskog utjecaja što utječe na poravnanje.

Izazovi ravnoteže radne ploče: treba se uvjeriti da je ogromna radna platforma zaista okomita na sustav kretanja.

Sustavi s dva/više motora: Ovi, koji se koriste kod nekih većih pisača, moraju biti savršeno usklađeni kako ne bi predstavljali opasnost od zakočenja.

Osnovni alati:

Precizni mjerilo za kvadrat (ili točan blok pod pravim kutom), ili

Dobar set mjerila (preporučeno 0,05 mm, 0,10 mm, 0,20 mm)

Kazalni mjerilo s magnetskom podlogom (preporučuje se za potvrdu preciznosti)

Pouzdan vodovag (samo za početno postavljanje okvira)

Ključevi i imbus ključevi potrebni za vašu mašinu.

Vodič za kalibraciju korak po korak:

1. Temelj prvo: Kvadratnost okvira i nosača:

• Isključite stroj. Uvjerite se da je na čvrstoj, ravnoj površini (vodovag se može koristiti samo za postizanje početne stabilnosti).

• Pažljivo provjerite mjerilom za kvadrat da su vertikalni dijelovi okvira okomiti na bazu, s obje strane, te okomiti (sprijeda/straga) i s desne i lijeve strane. Sve veze okvira trebaju biti stegnute.

• Kod strojeva na portalni stil, provjerite je li X-osi portal okomit na vertikalne Z-osi šine na prednjoj i stražnjoj strani. Prilagodite prema uputama proizvođača (obično to znači olabaviti spojnice ili motorna učvršćenja).

2. Vertikalna poravnata Z-vretena:

• Pritisnite mjerilo za okomicu uz svaki Z-osni vodilica vretena ili šipku. Promatrajte stvarnu vertikalnost cijele duljine, posebno na vrhu i dnu. Svaki izrazit luka ili nagib mora se ispraviti.

• Lagano zatresite gornji i/ili donji pričvrsni dio šipke. Tapnite ili pomaknite šipku blagim udarcem i poravnajte ju potpuno vertikalno uz mjerilo. Pažljivo ponovno zategnite pričvrsne točke kako ne biste stvorili novi napon.

3. Sinkronizacija dvostrukih/višestrukih Z motora (ako je primjenjivo):

• Ručna metoda (zahtijeva pažnju): Isključite motore (a zatim isključite struju (ako je moguće)). Oba Z-osna spojnice na strani motora treba okretati istim smjerom i istovremeno rukama kako bi se podigla ili spustila konstrukcija simetrično. Usporedite kvadrat s referentnom točkom na konstrukciji i okviru kako biste bili sigurni da ostaje paralelan s podlogom dok se kreće.

• Metoda uz pomoć softvera (preporučena): Većina strojeva s velikim pisaćim firmverima ima postupak poravnavanja Z-os. Oni blago pokreću svaki motor pojedinačno, prateći potrošnju struje ili detekciju zaustavljanja kako bi automatski izravnali konstrukciju oko okvira. Budite vrlo oprezni prilikom slijedanja uputa firmvera.

4. Ustvrđivanje okomitosti: Z-os prema ploči za izradu:

• Pozicionirajte Z-os.

• Metoda 1 (Mjerila i Kvadrat): Postavite strojarski kvadrat okomito na očištanu ploču. Podesite tako da jedna stranica kvadrata dodiruje ploču, a druga stranica bude usmjerena u istom smjeru kao najbliži Z-osovinski šipak/vođica. Umjestite odgovarajuće mjerilo između kvadrata i dijela Z osovine na dva i četiri mjesta. Svaki razmak ukazuje na nagib. Ravnine se najmanje zakreću prema relevantnoj strani ugradnje ploče ili ugradnje portalnog sustava. Ponovite na nekoliko mjesta na ploči.

• Metoda 2 (Mjerni kazaljnik - zlatni standard): Postavite (trajno pričvrstite) bazu mjernog kazaljnika na ispisnu glavu ili ugađaj alata. Postavite vrh kazaljnika uz fiksnu okomitu referentnu površinu na okviru, ali ne na ploči za izradu. Polako pomičite Z-os gore-dolje i pređite veći dio njenog hoda (npr. 200 mm). Otklon kazaljnika ne smije biti velik (trebao bi biti < 0,05 mm po hodu). Veliki otklon znači da Z-gibanje nije okomito i da je potrebna korekcija okvira ili štapa. Ponovite postupak za sve ostale važne referentne točke.

5. Uređivanje niveliranja ploče za izradu (Tramming):

• Važno je napomenuti da ovaj proces već osigurava da je vaše Z-gibanje okomito na okvir.

• Ohladite ležaj i mlaznicu i dovedite ih na normalnu temperaturu ispisa. Kod većih ploča važna je termalna ekspanzija.

• Početak Z-osi.

• Uključivanje/isključivanje koraknih motora.

• Kada ručno postavite početnu točku, pomaknite ispisnu glavu do svakog kuta ploče i do sredine ploče.

• Umjesto svake točke umetnite mjerilo u obliku listića između mlaznice i postelje. Izvršite fine prilagodbe, radijte na svakom vijku u kutu postelje kako bi se postigao jednak minimalni otpor na mjerilu u svim pozicijama. Ponavljanje se izvodi nekoliko puta jer prilagodba jednog kuta utječe na druge kutove. Provjera središnje točke pokazat će vam da je sama postelja izobličena.

6. Konačne provjere i test tiska:

Pronađite novo mjesto za stroj.

Napravite veliki jednoslojni test tiska (npr. tanki pravokutnik koji pokriva većinu postelje). Pogledajte ekstrudiranje prvog sloja:

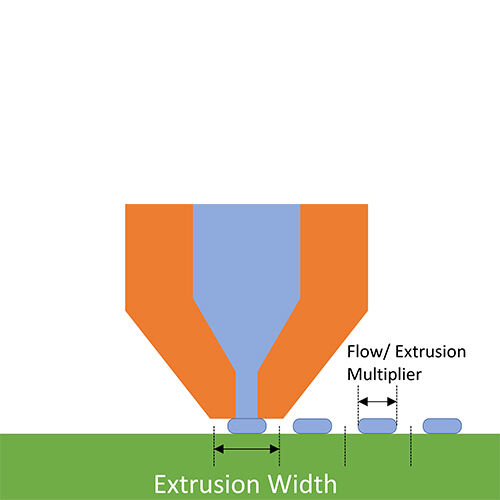

Jednoliko spljoštenje: Linije moraju imati jednaku širinu i visinu na cijeloj postelji.

Prianjanje: Mora biti gusto i s jednolikim prianjanjem svuda.

Bez grebanja: Mlaznica ne smije orezivati postelju.

Bez pukotina: Jedna linija treba prelaziti u drugu bez vidljivih razmaka.

Dodatno prilagodite niveliranje postelje temeljeno na rezultatima test tiska.

Održavanje je ključno:

Postoje pisači većeg formata, koji su više optereženi. Obratite pažnju na poravnanje Z-osi redovno, jer odstupanja izazivaju vibracije, promjene temperature i trošenje. Ovo su neke provjere koje možete uključiti u svoj preventivni održavanje, posebno prije važnih i većih ispisa.

Zaključak:

Uspješan 3D štampanje velikog formata temelji se na preciznom poravnanju Z-osi. Još opsežniji kada se primjenjuje na većoj razini, postupak ovisi o nekoliko osnovnih načela: okomitost strukture, provjera gibanja pod pravim kutom i temeljito niveliranje posteljice. Posvetivši vrijeme učenju ove kalibracije, možete ukloniti značajni uzrok neuspjelih ispisa i iskoristiti stvarni potencijal vašeg uređaja za pouzdano izradu prekrasnih dijelova velikih dimenzija. Nikada nemojte dopustiti da greške Z-osi smanje vaše mogućnosti!

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

BE

BE

HY

HY

KA

KA

LO

LO

LA

LA

MN

MN

NE

NE

SO

SO

MY

MY

KK

KK

UZ

UZ