The Future of Commercial Printing: Embracing 3D Printing Technology

Introduction

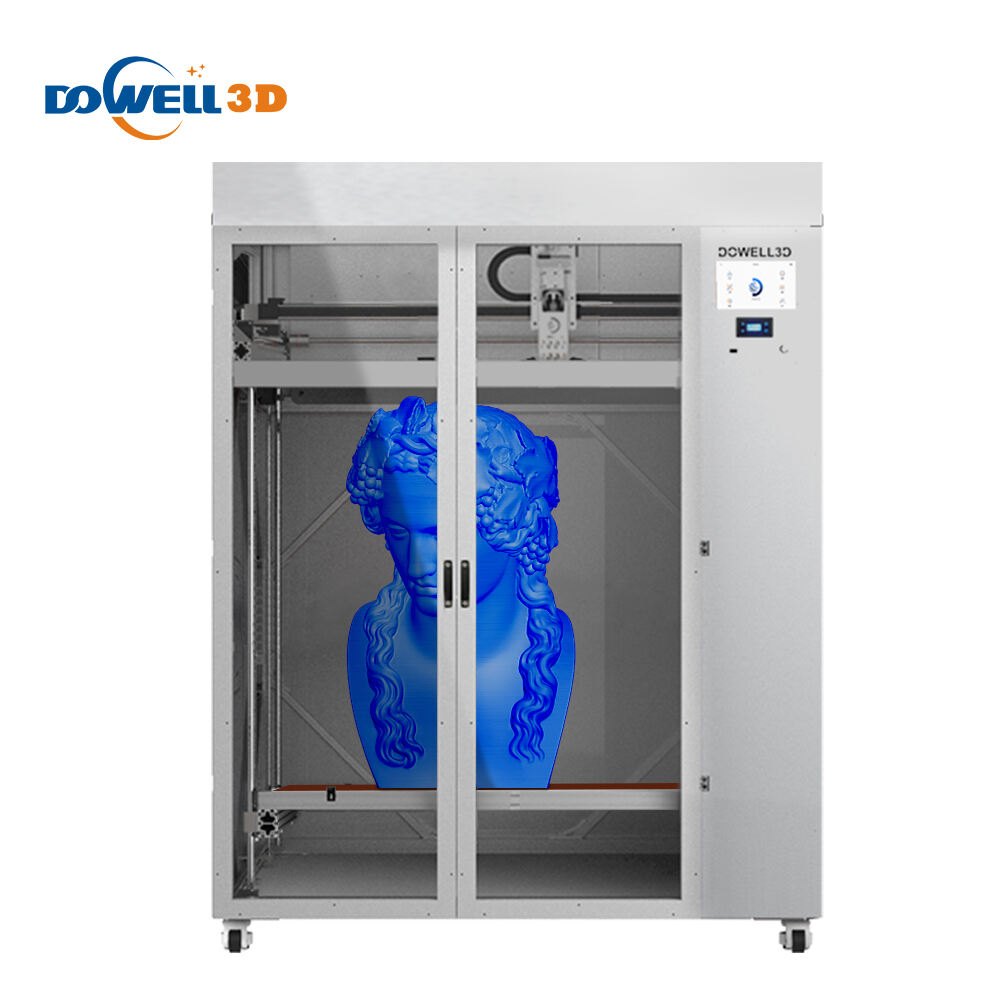

Have you ever imagined having access to print out physical objects in three-dimensions right from your computer? the magic that 3D printers can do. In recent years, this technology has become a game-changer in the commercial printing space, and businesses are now embracing 3D printing from Dowell 3D for its numerous benefits. We will explore the advantages of 3D printers for commercial use, how to use the technology, safety concerns, quality assurance, and applications.

3D printers have taken the world by storm with the numerous advantages they offer. Firstly, they enhance creativity and allows businesses to create unique and highly customized products that are hard to find elsewhere. The ability to print out complex designs easily has increased the scope for innovation and creating new products.

Additionally, 3D printers reduce the cost and time spent on production, thus helping to increase productivity. In comparison to traditional manufacturing techniques, producing using 3D technology such as Dowell 3D tpu 3d printer filament cuts down the workforce required, producing less waste, and saves the environment. Another advantage of 3D printing is that it improves efficiency in prototyping, enabling businesses to produce various models quickly and cheaply before going into mass production.

Innovation in 3D printing technology has been revolutionary in recent years, with the introduction of more advanced and sophisticated 3D printers. 3D printing technology is becoming more robust, enabling businesses to print out objects with more detail and complexity. Also, the development of new materials has increased the range of products that can be printed using 3D printers.

The advancements in 3D printing technology from Dowell 3D have not been limited to hardware alone, as software developments have helped create more versatile designs, using complex geometries and different materials. As a result, businesses have access to an endless range of possibilities to experiment with new shapes, textures, and colors, all made possible through 3D printing technology.

Although 3D printing technology and also the Dowell 3D 3d filament has numerous advantages, there are some safety concerns to be aware of. The emissions from 3D printers must be monitored to ensure that they don't pose a risk to the health of workers in the production process. It is essential to check that the materials used in 3D printing are safe to use and meet the required safety regulations.

The use of Dowell 3D product like 3D printing technology is becoming more widespread in various industries, including manufacturing, healthcare, architecture, and the automotive industry. Manufacturing industries are using 3D printing technology to produce small and intricate parts that are hard to produce with traditional manufacturing techniques. The automotive industry is using 3D printing technology to produce interior parts, including custom dashboards, while architects are using it to print out 3D models of their building designs.

The business is protected under intellectual property rights. It 3d printer for commercial use from SGS, FCC, CE and more. It has also been identified as a Luoyang high-tech enterprises. Each products is rigorously tested before it leaves the factory, and an evaluations reports is issued.

The 3d printer for commercial use is FDM/FGF printers, as well 3D materials. The current main products includes FDM 3D printers made plastic, FGF 3D printers made of plastic particles, and 3D materials, which includes ABS, PETG, PLA, TPU, Carbon fiber Glass fibers, PP, and various composites materials.

Dowell's primary customers research institutes, universities as well as technology-related companies. More than 20,000 customers are serviced across the globe, and they 3d printer for commercial use. They offer secures and reliable logistical services to ensures each product reaches it clients in total and full.

Dowell is a manufacturing shops and R and D centers. It has six series that includes more than 100 designs of products and more than 300 varieties of spares parts 3d printer for commercial use. Dowell has received numerous international patents and certifications.

Using 3D printing technology and also Dowell 3D 3d printer machine is relatively easy and straightforward, and it requires minimal training to be proficient in using the technology. First, you need to design your product using a 3D modeling software or download it from an online repository. Once you have the design, transfer it to the 3D printer using an USB flash drive or a Wi-Fi connection.

After transferring the design, the printer will commence the printing process by heating the material and using it to print out the object layer by layer. Once the printing process is complete, you can remove the product from the printer and clean it using appropriate cleaning agents.

Service and quality assurance are critical factors in the 3D printing process. You need to ensure that your Dowell 3D product like 3D printer is always in good condition, well-maintained and performs optimally to avoid machine failure. Quality assurance is equally essential to ensure that the products produced are of high quality and meet customer expectations.

3D printing technology has numerous applications, including prototyping, creating medical implants, models, jewelry, and even food same with Dowell 3D fdm 3d printer. This technology is set to revolutionize many industries and will help boost productivity and innovation. As demand for customized products continue to grow, 3D printing technology will become more essential in the production process.