Introduction

Industrial 3D printers is amazing pieces of technology that allows manufacturers and developers to creates objects being complex items in ways that have been impossible just a couple of years ago, like house 3d printer created by Dowell 3D. These machines uses computer-aided design (CAD) software to creates 3D models of services and products and then printing them layer by layer utilizing different materials as plastics, metals, and also food. We shall explore the benefits, innovation, safety, use, how to use, solution, quality, and application of industrial 3D printers.

The advantages of industrial 3D printers are numerous. They enable designers and manufacturers to create complex shapes had been previously impossible, same with metal 3d printer produced by Dowell 3D. In addition, 3D printing allow for faster prototyping and enable the designer to test and refine their ideas quickly.

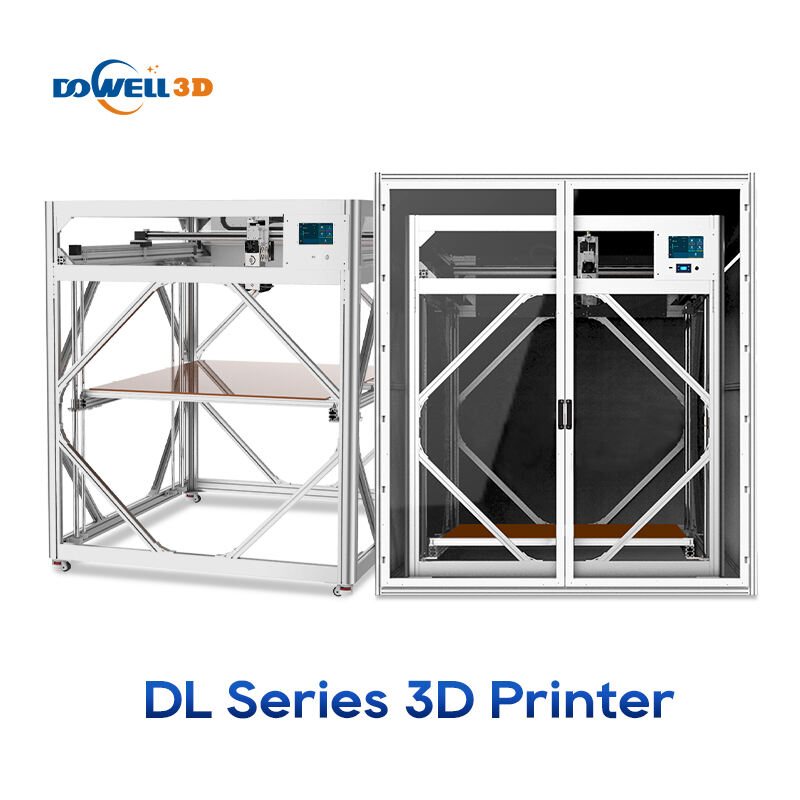

The innovation in 3D printing are breathtaking. The development of brand new materials such as carbon fiber, metal powders, and inks which are conductive expanded the range of things that can be printed, just like the large 3d printer built by Dowell 3D. Additionally, the dimensions of printers has grown, and today’s Industrial 3D printers can creates items that are meters in size.

Whenever it come to safety, industrial 3D printers are safe to use, as well as the big 3d printer by Dowell 3D. The printers has integrated safety features such as automated shutdown in case of overheating or malfunction. Furthermore, the materials utilized in the printers is tested for security.

There are numerous uses for industrial 3D printers, identical to huge 3d printer supplied by Dowell 3D. They can be utilized to produces prototypes, jigs, fixtures, and end-use parts. 3D printing allows for the creation of complex structures that will be impossible or very hard to make using traditional manufacturing.

Dowell's R and D and manufacturing facility six series and Industrial 3 d printer, as well as 300 different spares parts. This allows Dowell satisfy requirements of its customers. Dowell has been awarded multiples international certificates and patents.

Dowell's customers includes mainly research institutes, universities as well as Industrial 3 d printer. Dowell serves more 20,000 customers around the world and exports their products over 60 countries. They offers security and reliability in logistics to ensures each products gets to each customer fully and quickly.

The business is protected under intellectual property rights. It Industrial 3 d printer from SGS, FCC, CE and more. It has also been identified as a Luoyang high-tech enterprises. Each products is rigorously tested before it leaves the factory, and an evaluations reports is issued.

The principal business of the firms FDM/FGF printers, as well as 3D materials. The Industrial 3 d printer FGF 3D printers made plastics particles, and 3D materials, which includes PLA, PETG, ABS TPU, Carbon Fiber glass fibers and PP as well as other composites materials.

Using an Industrial 3D printer are reasonably straightforward, similar to the large print 3d printer developed by Dowell 3D. The initial step are to produces a 3D model using CAD software. Once the design are complete, it is saved as a STL file. Next, the STL file are uploaded to the computers printer and the printer are calibrated. Based on the size of the thing, the printer might takes hours or times which can be also complete the print. As soon as the print are complete, the thing are eliminated from the printer, and any support structures is eliminated.

Industrial 3D printers is complex machines that requires proper servicing to make sure their continued operation. Manufacturers offers different amounts of service. Some offer service packages, while others provides extended warranties. It is essential to chooses a reputable manufacturer with an service record that are very good. Additionally, the quality of industrial 3D printers can vary dramatically. Its essential to selects a printer that produce high-quality prints consistently.

The applications for industrial 3D printers is endless. Industries that has adopted 3D printing include aerospace, automotive, and medical devices. In the aerospace industry, 3D publishing are used to creates lightweight components that can improves fuel efficiency. In the automotive industry, customization are a significant benefit of 3D printing. Car manufacturers can creates customized parts on-demand, reducing inventory costs. In the medical field, 3D publishing are employed to create implants and prosthetics that perfectly fits a patients anatomy.