What is ABS 3D Printing Material and why should you use it? ABS 3D Printing material is a great innovation in the world of 3D printing. If you are a big fan of creating your own designs and 3D printing them, then you should definitely give ABS a try. Dowell 3D dual extrusion 3d printer is made of a thermoplastic polymer that enables it to withstand high temperatures. This article will explain the advantages of ABS 3D Printing material, how to use it, safety measures to take, its application, and the quality of service you can expect.

ABS 3D Printing material has many advantages over other 3D printing materials. First of all, ABS is highly durable and strong. This means that you can create 3D print designs that are sturdy and can withstand impacts without breaking. Additionally, ABS is a lightweight material, which makes it easy to handle and work with. You can create large designs without worrying about the weight of the finished product. Another advantage of Dowell 3D pla plastic 3d printing is that it is easy to paint and apply coatings to. This is great for those who want to customize their designs and give them an unique artistic touch. The material is also resistant to UV rays, meaning your designs will not fade over time if exposed to the sun.

ABS 3D Printing Material is one of the most innovative Dowell 3D large scale 3d printing available today. This is because it is highly adaptable and can be used for a variety of purposes. You can create anything from toys and games to household items and parts for machinery. The possibilities are endless.

When using ABS 3D Printing Material, it is important to take safety measures to avoid any risks. You should always use a well-ventilated area when Dowell 3D pellet 3d printer. This is because the material releases fumes that can be toxic when inhaled. Additionally, you should wear protective gear, such as gloves and a respirator, to protect yourself from fumes and particles.

Using ABS 3D Printing material is relatively easy. First, you need to load the material into your 3D printer. Once this is done, you can choose your design and start printing. The printing process might take some time, depending on the complexity of the design. When the printing is complete, carefully remove your design from the printer bed. It is important to note that Dowell 3D big scale 3d printer must be printed at high temperatures, usually between 220 and 250 degrees Celsius.

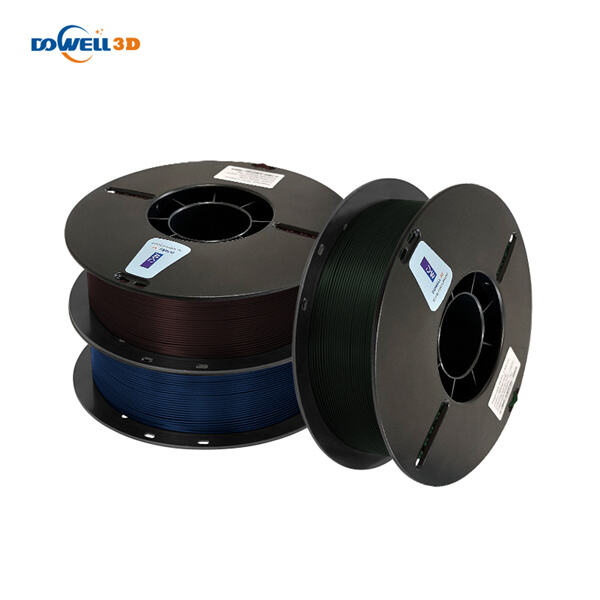

The main business of the firms is FDM/FGF printers, as well as 3D materials. Our most popular products includes FDM plastic filament printers as well as Abs 3d printing material 3D printers. 3D materials includes PLA, PETG ABS, TPU, Glass Fiber, Carbon Fiber, PP and many other composites materials.

Dowell's Abs 3d printing material, universities as well as technology-related companies. Dowell serves more s20,000 customers across globe, and exports to more 60 nations, offering security and reliability logistics to ensures that each items gets each customers fully and quickly.

Dowell has it owns manufacturing workshops as well a R and D centers. Abs 3d printing material and more than 300 different kinds spares components to satisfy diverse needs of customers. Dowell been awarded numerous international patents and certifications.

The company has been certified by CE, SGS, FCC and other certifications, has over 40 patents, is protected by intellectual property rights that are independent, and Abs 3d printing material. Each product is thoroughly tested before it leaves the factory. the test report is made available.

When it comes to Dowell 3D 3d filament machine, you can expect high-quality service. The material is in high demand, meaning that manufacturers are always looking for ways to improve it. You can expect consistent quality from the material, whether you are printing large or small designs.

ABS 3D Printing Material has a wide range of applications. It can be used to create toys, games, and figurines. Additionally, it is great for creating household items, such as containers and hooks. Dowell 3D filament pla 1.75 mm is also used for automotive parts and machinery, as it can withstand high temperatures and pressure. The material is also great for creating prototypes, used for product testing and design iteration.