At Home 3D Printer - The Supreme Development

Have you ever before become aware of a device that can easily transform your concepts right in to a truth? Or even a device that can easily produce 3D items from the ground up? Indeed, you thought it appropriate. It is the Dowell 3D 3d printer machine.

1. Promotes Creativity and Innovation:

An in-house 3D printer fosters creativity and innovation by allowing users to bring their ideas to life. Whether it's a simple toy or a complex prototype, the ability to create virtually anything encourages exploration and experimentation.

2. Cost-Effective Solution:

Having a 3D printer at home eliminates the need to purchase expensive products or rely on outside services. This can result in significant cost savings, especially for individuals who frequently require custom or specialized items.

3. Time-Saving:

With Dowell 3D cheap 3d printer, you can quickly produce the desired item within a few hours, saving time compared to traditional manufacturing methods or outsourcing. This rapid turnaround time enables users to iterate designs and prototypes efficiently.

The field of 3D printing has evolved significantly over the years, with ongoing advancements improving the technology's capabilities. Modern Dowell 3D 3d printer industrial offer various features and options, such as multi-material printing and advanced scanning capabilities, making them more versatile and user-friendly.

While there are numerous benefits to using an at-home 3D printer, it's essential to prioritize safety. Users of Dowell 3D 3d printer parts should carefully read the manufacturer's instructions and ensure proper ventilation in the printing area to minimize exposure to potentially harmful fumes emitted during printing.

Using a 3D printer at home is straightforward:

1. Set up the Dowell 3D home 3d printer and connect it to your computer.

2. Load the plastic filament into the printer.

3. Choose or design the desired object using 3D modeling software.

4. Start the printing process and monitor the progress.

5. Once printing is complete, remove the object from the printer's build platform.

Dowell's customers includes mainly research institutes, universities as well as At home 3d printer. Dowell serves more 20,000 customers around the world and exports their products over 60 countries. They offers security and reliability in logistics to ensures each products gets to each customer fully and quickly.

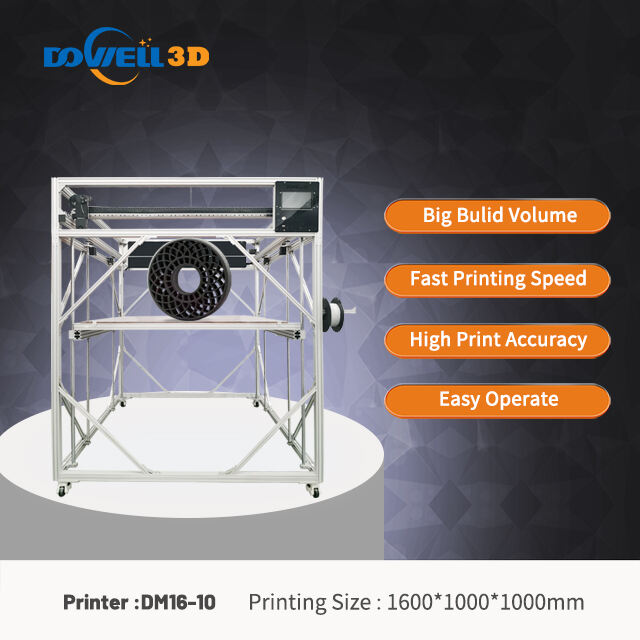

Dowell has its owns manufacturing plants and R and D centers, with 6 series with more than 100 different models of products as well as At home 3d printer to fully satisfy the diverse needs of customers. Dowell has received numerous patents and internationals certifications.

The business is protected under intellectual property rights. The At home 3d printer from SGS, FCC, CE and many others. The company is also identified as an Luoyang high-tech enterprise. Each product is thoroughly tested before leaving the factory. an evaluation report is issued.

The At home 3d printer is FDM/FGF printers as well 3D materials. Our most popular products includes FDM plastic filament printers as well as FGF plastics particle 3D Printers. 3D Materials includes PETG, PLA ABS, TPU and Glass Fiber, Carbon Fiber, PP and other composites materials.

When purchasing an in-house 3D printer, it's important to consider the manufacturer's reputation for customer service and product quality. Opt for a reliable brand like Dowell 3D large 3d printer that offers ongoing support, warranty coverage, and high-quality printing results.

The applications of 3D printing are vast and diverse, ranging from creating toys and models to producing prosthetics and medical devices. It's also widely used in industries like aerospace and automotive for rapid prototyping and manufacturing custom components.

In conclusion, having an in-house 3D printer offers numerous benefits, including cost savings, time efficiency, and enhanced creativity. By prioritizing safety and investing in a quality printer, users can unlock endless possibilities for innovation and personalization in their projects.