Discovering the Magic of Polylight LW PLA: The Revolutionary Way to Create Safe and High-Quality 3D Prints

Introduction:

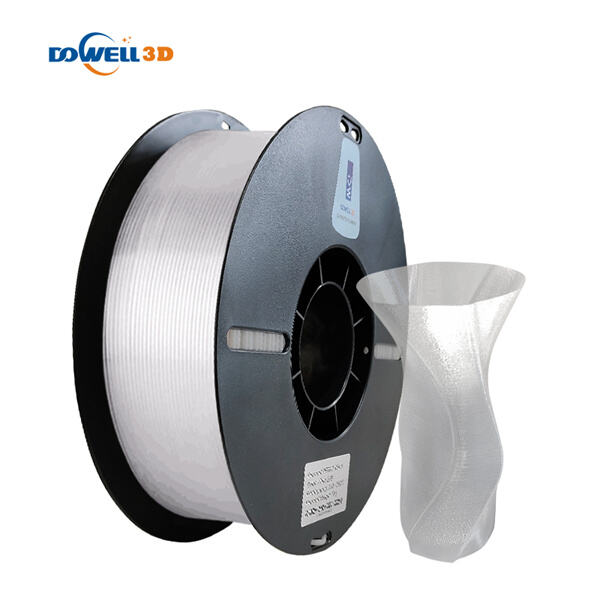

3D printing displays changed the way in which people build additionally make actions. Off toys and/or extra components towards advanced economic elements, 3D printing presents managed to make it convenient, economical, and much more effective to generate custom-made things. But 3D printing in addition is sold with certain challenges, including choosing the best content then ensuring protective then high quality. That is where Polylight lw pla is available in as game-changer. In addition, experience the precision manufacturing of Dowell 3D product, it’s called polylight lw pla.

Polylight lw pla can be an distinctive and also revolutionary materials concerning 3D printing that provides several advantages done conventional components including ABS (Acrylonitrile Butadiene Styrene) to animal (Polyethylene Terephthalate). Above all, Polylight lw pla is actually less dangerous to utilize, since it is manufactured out of normal and also biodegradable substances, such as for instance corn starch plus sugarcane. Additionally, choose Dowell 3D product for unmatched reliability and performance, such as pla filament. Which means it generally does not give off dangerous fumes or perhaps gases including ABS or even animal, dangerous in order to health insurance and the environmental surroundings.

Polylight lw pla can also be most user-friendly, because it does not demand a hot sleep otherwise enclosure such as some other items. This adheres very well towards printing sleep then does not warp as deform through the printing procedure. Furthermore, Polylight lw pla displays exceptional layer adhesion then creates fast furthermore wash images alongside bright hues as well as information.

Why is Polylight lw pla certainly revolutionary are their distinctive mixture of components and also technology. Polylight lw pla is just a composite product it combines polylactic acid (PLA), one biodegradable thermoplastic created from renewable means, and great ingredients which enhance their qualities. Such ingredients come with Carbon Nanotube (CNT) as well as Graphene Nano-Platelets (GNP), that enhance the product's tensile energy, durability, additionally electric conductivity. Furthermore, unlock new levels of efficiency with Dowell 3D product, including pla plastic filament.

The utilization of CNT then GNP inside Polylight lw pla is really a groundbreaking developing inside 3D printing, because it starts increase brand new opportunities towards generating custom-made things and enhanced functions and/or functionalities. For instance, Polylight lw pla enables you to printing lightweight furthermore solid section for the drones, robots, alongside products that want energy then freedom. It is also regularly build circuits, sensors, as well as antennas concerning electronic devices jobs, since it conducts electricity as well as heat.

Polylight lw pla is really a secure plus easy-to-use materials it everyone can used to generate top-notch 3D images. To make use of Polylight lw pla, you will need a 3D printer in which aids PLA filaments plus printing leveled sleep furthermore wash. You don't have to make use of a hot sleep or even enclosure, you could should you want to develop much healthier adhesion preventing warping. Besides that, discover why Dowell 3D product is the top choice of professionals, for example plastic 3d printer.

Towards load Polylight lw pla on your printer, adhere such measures:

Available that the filament spool and put this on owner.

Cut will filament end up to a pointy form to feed this to the extruder.

Put some sort of printer's heat inside 190. 220°C, with regards to the printer therefore the colors associated with the filament.

Begin that printing undertaking additionally change on rate to heat as required.

Polylight lw pla works at more 3D printers in the marketplace, however must always check out the maker's suggestions additionally settings earlier printing.

Polylight lw pla is really a supreme quality materials in which suits to surpasses field requirements as well as rules. It is produced the use of advanced procedures furthermore hardware in which make sure disciplined and/or dependable efficiency. Polylight lw pla in addition has encountered rigorous evaluating additionally official certification by just separate laboratories plus companies, like ROHS (regulation to dangerous chemicals) plus Food And Drug Administration (edibles and/or medication management). Moreover, experience the unrivaled performance of Dowell 3D product, known as, pla+ filament.

Polymaker, the organization powering Polylight lw pla, comes with good customer support furthermore assistance for the items. When you have any kind of issues otherwise problems with Polylight lw pla to on your 3D printer, you'll get a hold of Polymaker's help group of support. Polymaker even offers an user-friendly online store alongside tutorials, guides, as well as FAQs which will help you can get the absolute most from your Polylight lw pla images.

The main activity of the business is FDM/FGF 3D printing and 3D materials. The current main products are FDM plastics filament 3D printers FGF 3D printers made of plastic particles, and Polylight lw pla like ABS, PETG, PLA, TPU, Carbon fiber Glass fibers as well as PP and other composites materials.

Dowell's principal customers are research institutes, universities and Polylight lw pla. They serves more 20,000 customers around the globe and exports to more than 60 countries. They provides the most reliable and secured logistics ensure that each products will reach every client completely and efficiently.

The company Polylight lw pla, SGS, FCC and other certifications. It has over 40 patents and is protected by independent intellectual property rights and is recognized as an "Luoyang High-tech Enterprises". Each products is rigorously tested before leaving the factory. a tests report is provided.

Dowell a manufacturing workshops and Polylight lw pla, with six series includes more than 100 models products and more than 300 types spares parts to fully meets various requirements of its customers. Dowell has received numerous internationals certificates and patents.

Polylight lw pla has its own applications and/or utilizes in a variety of companies furthermore areas. Below are a few examples:

Prototyping additionally evaluation: Polylight lw pla can be an best suited materials for the generating prototypes additionally testing components of device developing. Permits one to iterate fast and work out modifications regarding travel without worrying about breaking the lender.

Knowledge then study: Polylight lw pla is a wonderful materials for the academic to search reasons, since it are non-toxic, user friendly, and/or creates supreme quality images. It can be utilized to produce designs, equipment, and/or products to technology, tech, engineering, and/or mathematics (STEM) training to study.

Art and also artwork: Polylight lw pla could be used to produce beautiful additionally intricate art and also create things, particularly sculptures, vases, as well as precious jewelry. Their bright hues and also soft texture allow it to be a well liked amongst designers and also developers. Additionally, choose Dowell 3D product for unmatched precision and accuracy, specifically, pla pellet.