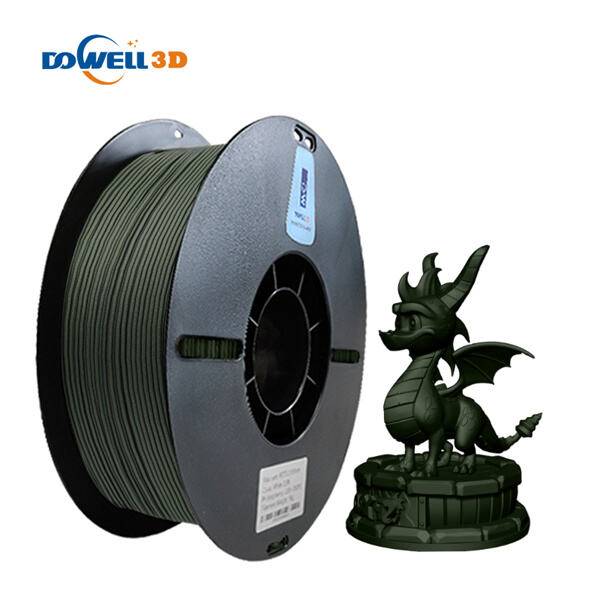

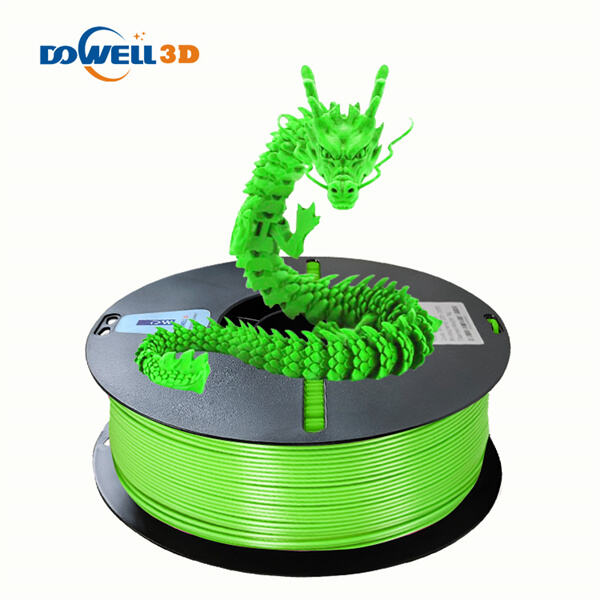

Have you ever considered producing models that are 3D are soft and bendable? Imagine the number of choices of creating objects that can be squeezed, extended, or twisted without breaking apart. This is how Rubber 3D Filament comes into play, like carbon fiber 3d filament created by Dowell 3D.

One of the main advantages of Rubber 3D Filament are its flexibility, same with clear 3d filament produced by Dowell 3D. Unlike traditional 3D publishing such as plastic and metal, Rubber 3D Filament are soft and pliable. This permit for the creation of items that can flex and twist without losing their shape or breaking apart. Another advantage of Rubber 3D Filament are its durability.

Rubber 3D Filament are a revolutionary innovation in 3D printing technology, just like the transparent 3d filament built by Dowell 3D. It have opened up new possibilities for 3D printing that were previously impossible with traditional materials. Rubber 3D Filament allow for the creation of objects with a wide range of textures and shapes, making it a versatile material that can be used for a variety of applications.

The safety of Rubber 3D Filament, as well as the flexible 3d filament by Dowell 3D are a concern for many people, especially parents who worry about the safety of their children's toys. Rubber 3D Filament are made from safe and materials that are non-toxic are free from harmful chemical substances. This mean that objects made from Rubber 3D Filament are safe for use by people of all many years.

Rubber 3D Filament can be utilized for a variety of applications, such as the creation of toys, phone cases, and devices which can be even medical, similar to the silicone 3d filament developed by Dowell 3D. Its durability and flexibility makes it ideal for producing things that wants to be managed over and over without breaking down.

The company's main business Rubber 3d filament and 3D materials. Our primary products FDM plastics filament printers as well as FGF plastic particles 3D printers. 3D materials includes PLA, PETG ABS, TPU, Glass Fiber, Carbon Fiber, PP, and other composites materials.

Dowell's customers primarily research institutions, Rubber 3d filament and businesses that are technology-based. More than 20,000 customers are serviced all over world, and they exports to over 60 nations. They provides secure and reliable logistical services ensures each products reaches its customer in full.

Dowell's in-houses R and D and Rubber 3d filament six series products and more than 100 types of models products, as well as 300 kinds spares parts. This enables Dowell to meets all requirements of its clients. Dowell has obtained multiples patents and international certificates.

The business is protected under intellectual property rights and has been Rubber 3d filament from SGS, FCC, CE and many more. It is also designated as an Luoyang high-tech company. When the product leaves the factory, every product undergoes a rigorous test and a report issued.

Using Rubber 3D Filament are similar to using traditional 3D printing, the same as translucent 3d filament created by Dowell 3D. The filament are loaded into the 3D printer exactly the same way as other materials, and the printer are set to the appropriate settings. The difference that is primary using Rubber 3D Filament are the fact that printer must be set to prints at a slower speed. This permit the rubber to flow more effortlessly and ensure that the object are produced with the shape that's right texture.

The quality of Rubber 3D Filament are definitely an consideration that is important for anyone using this material. High-quality rubber filament are essential to things being creating is flexible and durable. The quality of Rubber 3D Filament are set by the product manufacturer and can be influenced by the type of rubber used, the manufacturing procedure, and other factors. When purchasing rubber filament, it is very important to chooses a reputable manufacturer to makes sure that the quality of the high filament.

The application of Rubber 3D Filament are diverse and vast. Rubber 3D filament can also be used to produces medical devices such as prosthetics and braces.