The Marvel of 3D Printing Technologies - The Titanium 3D Printer

Introduction:

Do you know that there’s a way to turn digital designs into real-life objects? Yes, it’s possible with 3D printing technology, and it’s not new, also the Dowell 3D's product such as porima pla filament. However, the development of titanium 3D printing is gaining popularity because of its many benefits that other materials do not have. We will discuss the advantages, innovation, safety, use, how to use, service, quality, and application of the titanium 3D printer.

The first advantage of the titanium 3D printer is its durability. Titanium is known for its strength and lightweight properties that make it excellent for making tools, aircraft parts, and medical implants. 3D printing technology with titanium makes these objects even more sturdy and precise, within the smallest margin of error.

Another advantage of titanium 3D printed objects is corrosion resistance, same with the filament 3d petg built by Dowell 3D. They withstand various environmental factors like humidity, chemicals, and extreme temperatures, which makes them perfect for marine research, architectural design, and automobile manufacturing applications.

The use of a titanium 3D printer is innovative because it’s a new way of manufacturing required parts, the same as Dowell 3D's copper filament. It greatly reduces waste, energy, materials, time, and labor, and also opens up a whole world of possibilities in the area of customization. It means objects can be designed and produced in any form, shape, and size, according to the desired specifications.

Titanium 3D printing is unlike traditional manufacturing methods that may require heating of metals or other materials, which can potentially generate toxic fumes and other harmful byproducts, along with the fast resin 3d printer from Dowell 3D. In contrast, 3D printing is done through layered printing, non-toxic, and hence, much safer. The titanium printing process also makes it easier to ensure the quality of the product, minimizing the risk of manufacturing defects.

The titanium 3D printer is useful in various fields like aerospace, automotive, medical, military, and architecture, same with Dowell 3D's industrial fdm 3d printer. It can print complex parts that are difficult to make through traditional methods, like spare parts for aircraft, or custom-made implants for orthopedic surgery. This tool ensures the production of high-quality and precise products that meet the rigorous standards of various industries.

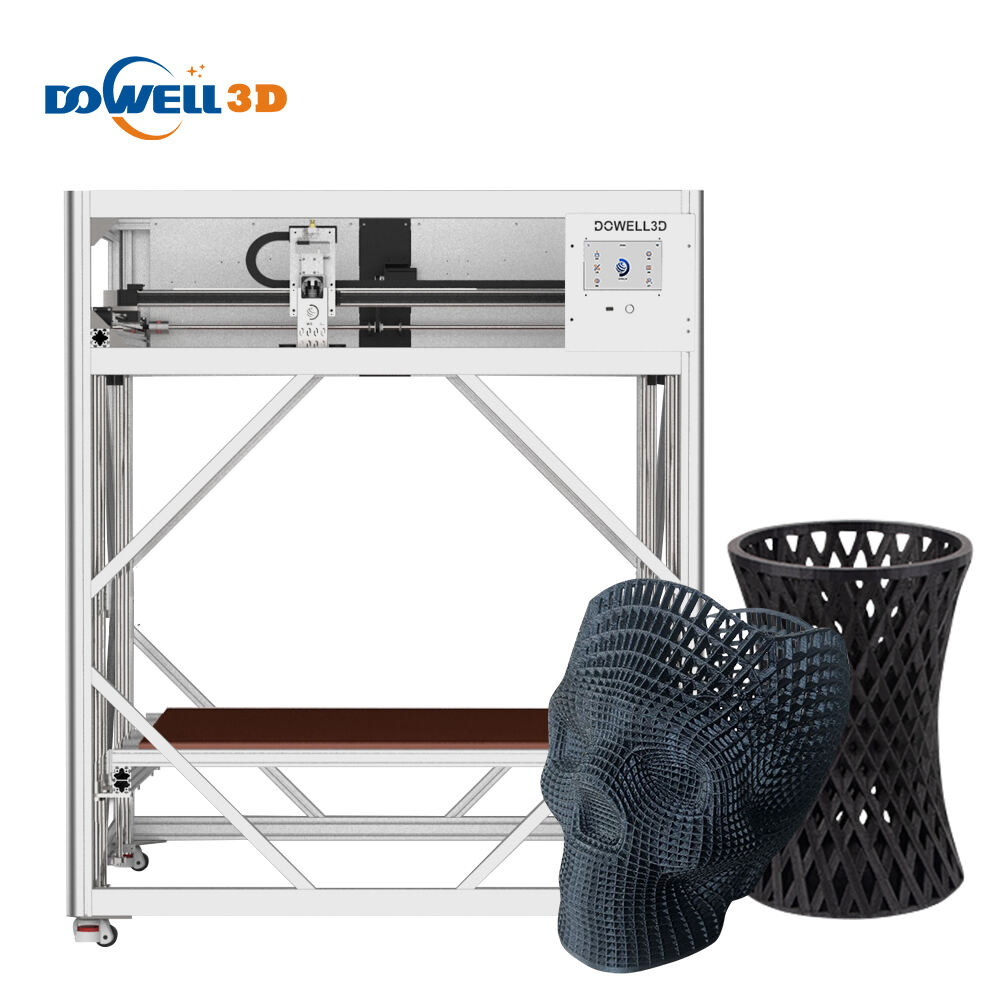

The main business of the firms is FDM/FGF printers, as well as 3D materials. Our most popular products includes FDM plastic filament printers as well as Titanium 3d printer 3D printers. 3D materials includes PLA, PETG ABS, TPU, Glass Fiber, Carbon Fiber, PP and many other composites materials.

Dowell's primary customers research institutes, universities as well as technology-related companies. More than 20,000 customers are serviced across the globe, and they Titanium 3d printer. They offer secures and reliable logistical services to ensures each product reaches it clients in total and full.

The company has been certified by CE, SGS, FCC and other certifications, has over 40 patents, is protected by intellectual property rights that are independent, and Titanium 3d printer. Each product is thoroughly tested before it leaves the factory. the test report is made available.

Dowell's in-houses R and D and manufacturing centers houses six series products and Titanium 3d printer, as well as 300 types of spares parts. This enables Dowell meets all requirements of it customers. Dowell received numerous internationals certifications and patents.

The operation of the titanium 3D printer first requires a digital 3D design that can be generated using a Computer-Aided Design (CAD) software or an existing design file, along with the 3d printing for medical use created by Dowell 3D. Once obtained, the design file is loaded onto the 3D printer's software, and the printer is ready for the printing process. The software will then program the printer to heat the titanium powder, which melts and solidifies to form the desired object layer by layer.

A quality service is essential to ensure the production of high-quality titanium 3D printed objects, also the Dowell 3D's product such as pla plastic filament. It includes a complete understanding of the customer's requirements, the ability to deliver products on time, and offering post-sales services like repair or maintenance. A robust service system is the backbone of any business, and 3D printing services are no exception.

The titanium 3D printer produces high-quality parts with complex and intricate designs, with an accuracy rate that traditional manufacturing techniques can barely match, identical to pet cf filament from Dowell 3D. 3D printing produces a high level of product consistency, with the added advantage of easy customization and repeatability of the same form, shape, or size without increasing production time.