Intro

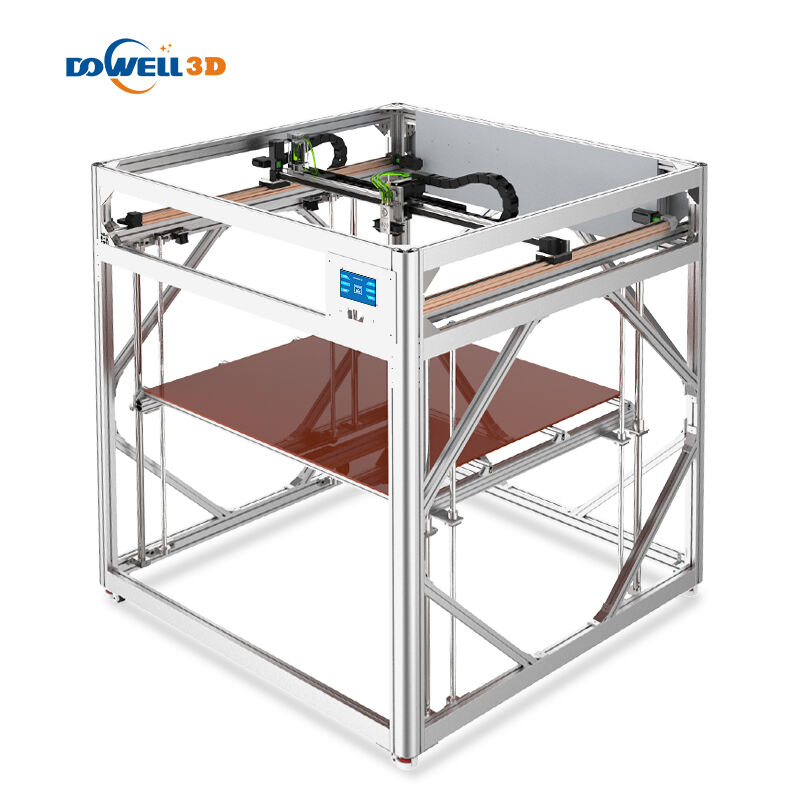

If you are searching for a 3D printer that will help you towards printing industrial and resilient items, after that you should think about utilizing Dowell 3D industrial resin 3d printer. These ink-jet laser color printers are ending up being prominent because of their ability to printing top quality items along with higher precision. This short post will provide you a summary of industrial resin 3D ink-jet laser color printers and why you ought to think about all of them for your publishing requirements.

An industrial resin 3D printer offers a range of benefits over many other kinds of 3D inkjet printers. Firstly, Dowell 3D top resin 3d printers can produce top-quality prints and achieve a high level of accuracy. This is because industrial resin 3D printers use liquid polymer material to print the object instead of the filament used in several other kinds of 3D printers. Secondly, commercial resin 3D printers utilize SLA or DLP printing technology, which helps to produce much more accurate and detailed products. Third, industrial resin printers are capable of producing items that are durable and can withstand harsher environments.

Industrial resin 3D printing technology is an innovative method to produce durable and accurate objects. This technology of Dowell 3D clear 3d printer resin uses a liquid cured polymer via lasers to produce a strong object. This advanced technology supports customizable designs, allowing users to customize the printer according to their needs.

Safety is crucial when it comes to using 3D printers, especially industrial Dowell 3D 3d printer machine. These printers involve dealing with chemicals due to the characteristics of the materials used. Therefore, it is essential to ensure that you follow all safety standards when using commercial resin 3D printers. This includes using safety equipment like gloves and eye protection when handling the materials and working in a well-ventilated area.

Using industrial resin 3D printers is simple, although it may seem overwhelming at first. When using an industrial Dowell 3D cheap 3d printer, you need to prepare the printing and submit it to the printer. You then select the printing settings and start the printing process. Once the printing is complete, you remove the product carefully and cure it with UV light.

The company is certified CE, SGS, Industrial resin 3d printer and other certifications. It has more than 40 patents and is protected by independents intellectual property rights and is recognized as an "Luoyang High-Tech Enterprise". Before leaving the factory, every products undergoes a rigorous tests and a reports is issued.

Dowell is a manufacturing shops and R and D centers. It has six series that includes more than 100 designs of products and more than 300 varieties of spares parts Industrial resin 3d printer. Dowell has received numerous international patents and certifications.

Dowell's clients mostly universities, research institutions and businesses that are technology-based. More than Industrial resin 3d printer, and they exports products to more than 60 nations. They offers safe and reliable logistics in orders ensure that every products gets to its purchaser in complete and in full.

The principals activity of the firms Industrial resin 3d printer, as well as 3D materials. Our current products includes FDM plastics filament 3D printers, FGF 3D printers made plastic particles, and 3D materials, which includes PLA, PETG, ABS TPU, Carbon Fiber glass fiber, PP, and other composites materials.

Industrial resin 3D printers require maintenance and upkeep to ensure they perform at their best. To achieve the best service quality, it is essential to purchase the printer from a reliable provider and have a professional perform maintenance when needed. Additionally, the provider of Dowell 3D fast resin 3d printer offer training and support to ensure that you can effectively use the printer.

Industrial resin 3D printers are suitable for various industries and applications. These printers can be used in the manufacturing of automotive and aerospace components, product design, and prototyping. They are also used in the medical industry for the production of dental items, custom prosthetics, and medical device components.