In the world of industrial 3D printing, success should be defined as more than simply finishing a print. But the real test is its dimensional stability, of a printed object’s maintaining an accurate shape and size, from digital design to finished physical part. In industrial use, even a small offset could cause a malfunction at assembly or in operation. Well, what are the fundamental engineering principles that make it possible for a big 3D printer to bring you this kind of pivotal accuracy and reliability? The secret is in the combined hardware of mechanical robustness, thermal management and modern control system.

The Importance of Structural Rigidity

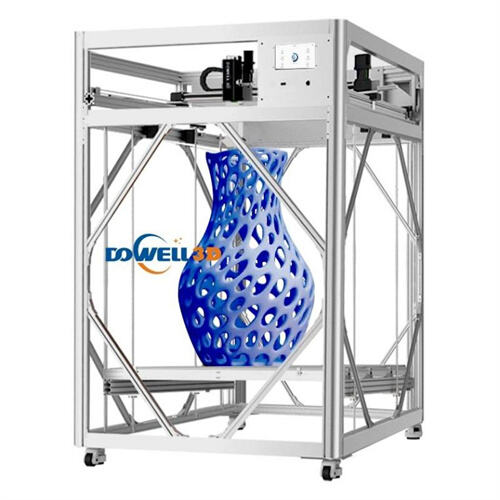

At the bottom of dimensional stability is a printer design. A large format printer contains moving parts that move quite a distance. The frame should not flex or resonance during print, which is very important. As such, a solid frame made with some high-grade materials is definitely necessary. Luoyang Dowell Electronics Technology Co., Ltd. utilizes a thickened 80mm durable frame with reinforced corners to create a frame with high torsional and lateral rigidity, preventing the moving platform from shaking or shifting during high-speed operation or high-load printing. The objective is to build an absolutely solid base that separates the act of printing from external interferences for proper stabilization and protection, you can expect everything will be as accurate as one plus one.

Advanced Motion System Design

And of course, a rigid frame is useless without a system to control movement just as effectively. The selection of motion devices determines the position accuracy. To eliminate backlash and enable movements to be repeated with ultra-precision linear guides with precision-ground lead screws or belt systems are needed. High-resolution stepper motors and sophisticated control algorithms are also used and add to the accuracy. These two systems are what when combined in sympathy with one another, can be used to make sure that the print head/move platform travel where they are supposed to with precision and accuracy applying layer after layer of material. This cautious control of the movement path is one of the factors which predetermine the total tolerance of parts.

Mastering Thermal Dynamics

Control of thermal and dimensional dovetailing, particularly with thermoplastics is, perhaps, the most difficult problem to control. When things get hot, they expand; when they cool off its contracts. In a high-volume build chamber, distortion, warping and curling can occur as well as the creation of internal tension. This needs to be overcome by having a controlled printing environment. The closed building environment is generally adopted where the temperature of the room/ chamber is maintained constant and the print is not subjected to drafts and changes in temperature. All of our printers are equipped with heated print platforms, which allow the printer to print the bottom layer without needing to cool the material in the bottom. Precise control of the thermal environment at every stage of printing significantly reduces internal mechanical stress, ultimately minimizing warping and deformation.

Accuracy of Material Handling and Software

Stability is then a function of the exact extrusion and deposition behaviour. It is important to have a uniform material flow. This involves the quality extrusion system with the ability to melt and feed filament, without sudden melt down or print holes. The printer software is equally important also. During slicing, advanced algorithms are used to create an optimized G-code of the 3D printer that may maximize the speed of the print and yield more precise prints using less energy consumption by the printer motors. This digital backbone of the printer is responsible for every physical aspect of it working in concert to produce a 3D object that exactly matches its digital counterpart on screen.

In short, large-format 3D printing owes this thanks to no single attribute, but rather because of the whole engineering that it offers. It requires such dedication to structural stability, fine motor control, smart thermal management, and seamless software that it almost beggars belief. At Luoyang Dowell Electronics Technology Co, Ltd, we incorporate all of these insights into the design and development to deliver DOWELL3D Printing systems that can meet the tough requirements demanded by industrial-scale additive manufacturing.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

BE

BE

HY

HY

KA

KA

LO

LO

LA

LA

MN

MN

NE

NE

SO

SO

MY

MY

KK

KK

UZ

UZ