Innovation, Use, Quality, and Safety

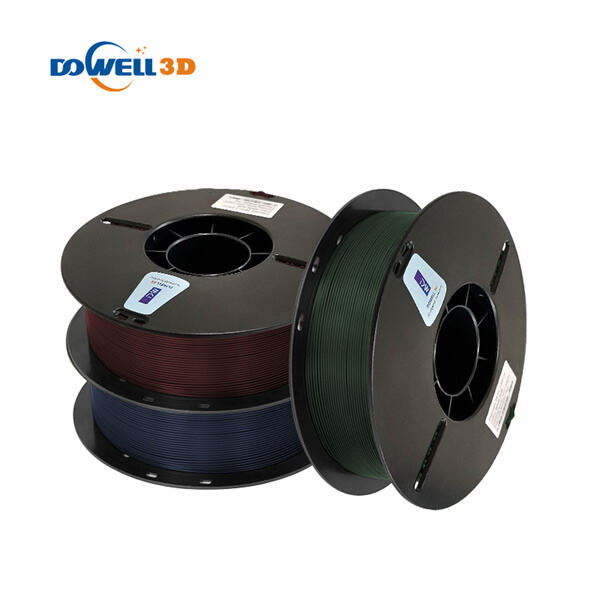

Are you curious about the nylon 3D printer? This innovative machine allows you to create objects using nylon, a strong and durable material, also the Dowell 3D's product such as 1 kg pla filament. We will explore the advantages of using a nylon 3D printer, how to use it, its safety, quality, and its many applications.

Nylon 3D printers have several advantages over other types of 3D printers, identical to wood filament 3d printer by Dowell 3D. First, nylon is a strong and flexible material that can produce complex, functional parts. Second, nylon is versatile enough to create both prototypes and final products. Third, the nylon 3D printer is fast and efficient, allowing you to produce multiple parts in a matter of hours.

Nylon 3D printing is an innovative technology that has revolutionized the way we produce objects, along with Dowell 3D's product multi color 3d printer. Traditional manufacturing methods like injection molding, machining, and casting can take weeks or even months to produce a single part. However, with nylon 3D printing, you can design, print, and test your parts in a matter of hours or days.

Safety is a crucial consideration when using a nylon 3D printer, same with the 3d filament from Dowell 3D. Like other 3D printers, the machine emits fumes that can be harmful if inhaled. It is essential to operate the printer in a well-ventilated area and wear protective gear like a mask and gloves. Additionally, you should never touch the printer's hot end during operation and keep it out of reach of children.

Using a nylon 3D printer is relatively easy, similar to the Dowell 3D's product like filament 2.85. First, you need to design your part using computer-aided design (CAD) software. Once your design is complete, upload your file to the 3D printer's software. Next, prepare your printer by leveling the bed and loading the nylon filament. Finally, press print and wait for your part to finish printing. Once it is done, remove the part from the printer's build plate and clean off any support materials.

The main business of the firms is FDM/FGF printers, as well as 3D materials. Our most popular products includes FDM plastic filament printers as well as Nylon 3d printer 3D printers. 3D materials includes PLA, PETG ABS, TPU, Glass Fiber, Carbon Fiber, PP and many other composites materials.

Dowell's Nylon 3d printer and manufacturing centers houses six series products and more 100 different types of models products, as well as 300 types spares parts. This enables Dowell to meet requirements of its clients. Dowell has been awarded numerous internationals patents and certifications.

The company has passed CE, Nylon 3d printer, FCC and other certifications. It has more than 40 patents and is protected by intellectual property rights that are independent, and has been recognized as an "Luoyang High-Tech Enterprise". Before it leaves the factory each products is rigorously tested and a reports is prepared.

Dowell's primary customers research institutes, universities as well as technology-related companies. More than 20,000 customers are serviced across the globe, and they Nylon 3d printer. They offer secures and reliable logistical services to ensures each product reaches it clients in total and full.

Nylon 3D printers produce parts with high quality and accuracy, also the transparent 3d filament by Dowell 3D. The machine's precise controls ensure that each part is made to exact specifications. Additionally, the strength and flexibility of nylon make it an excellent material for objects that need to withstand stress, pressure, and extreme temperatures. Nylon 3D printer parts are also resistant to wear and tear and can last for a long time, making them ideal for prototyping and final products.

The nylon 3D printer has many applications across various industries, as well as the Dowell 3D's 3d printer for wood. In the aerospace industry, nylon parts can be used in aircraft, missiles, and satellites. In automotive, nylon parts can be used for engine components, cooling systems, and interiors. In the medical industry, nylon parts can be used for prosthetics, surgical tools, and medical devices. Additionally, the fashion industry can use nylon 3D printers to create jewelry, accessories, and clothing designs.