What is 3D TPU and its Advantages

Let's start with a basic question: what is 3D TPU? 3D TPU stands for Three-Dimensional Thermoplastic Polyurethane. In simpler terms, it's a type of material commonly used in 3D printing. The innovative aspect of 3D TPU is that it's both flexible and durable - which makes it an ideal material for a variety of different products. Some of the advantages of using 3d tpu include:

- Flexibility: 3D TPU is known for its flexibility. It's a rubber-like material that can bend and stretch without breaking, making it suitable for a range of different applications.

- Durability: Not only is 3D TPU flexible by Dowell 3D, but it's also durable. It can withstand wear and tear, so products made from 3D TPU will last longer than those made from other materials.

- Chemical resistance: 3D TPU is resistant to chemicals, which means it won't degrade when exposed to certain substances.

3D TPU is an innovative material because it combines flexibility and durability in a way that wasn't possible with other materials. Traditional materials like plastic and metal have limitations when it comes to flexibility and durability. 3D TPU, on the other hand, has the best of both worlds. This innovation has allowed for the creation of products that were previously impossible to make. The tpu 3d filament by Dowell 3D has opened up new possibilities in industries like footwear, medical devices, and even automotive manufacturing.

When it comes to creating products, safety is always a top priority. Fortunately, 3D TPU is a safe material to use. It's non-toxic, food-safe, and doesn't release harmful chemicals when heated. That means products made from 3D TPU are safe for consumers to use. As for how to use 3D TPU by Dowell 3D, it's fairly straightforward. The material can be printed using a 3D printer, just like other materials. The tpu 3d printing filament is fed into the printer, melted, and then deposited in layers to create the desired shape. Once the printing process is complete, the product can be finished with sanding, painting, or other techniques.

When it comes to quality, 3D TPU is a premium material. Its flexibility and durability make it a choice material for creating high-quality products. Additionally, 3D TPU is available in a range of colors and finishes, allowing for customization and creativity. As for service, companies that offer 3D TPU printing services pride themselves on meeting the needs of their customers. Whether it's a large-scale production run or a one-off custom order, tpu 3d printer filament printing services by Dowell 3D are committed to delivering high-quality products on time and on budget.

The applications of 3D TPU are varied and vast. One of the most common uses of 3D TPU is in footwear. Brands like Adidas and Reebok have incorporated 3D TPU into their shoe designs to create a more comfortable and durable shoe. Medical devices are another area where 3D TPU is making an impact. Its flexibility and durability make it ideal for creating prosthetics and surgical tools. The automotive industry has also started using 3D TPU by Dowell 3D for creating parts that need to be flexible and durable. As 3D TPU technology advances, it's likely that even more industries will start incorporating the material into their products.

The company has been certified by CE, SGS, FCC and other certifications, has over 40 patents, is protected by intellectual property rights that are independent, and 3d tpu. Each product is thoroughly tested before it leaves the factory. the test report is made available.

Dowell's primary customers research institutes, universities as well as technology-related companies. More than 20,000 customers are serviced across the globe, and they 3d tpu. They offer secures and reliable logistical services to ensures each product reaches it clients in total and full.

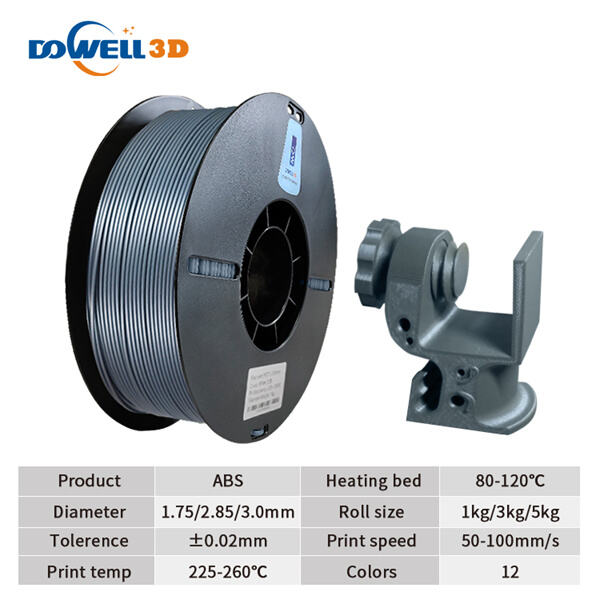

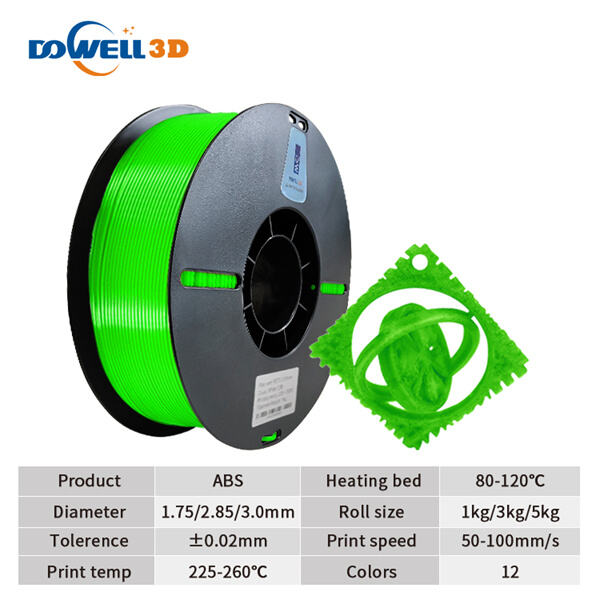

The main business of the firms FDM/FGF printers, as well as 3d tpu. Our main products includes FDM plastic filament printers and FGF plastic particles 3D Printers. 3D Materials include PLA, PETG ABS, TPU and Glass Fiber, Carbon Fiber, PP, and other composites materials.

Dowell's in-houses R and D and 3d tpu six series products and more than 100 types of models products, as well as 300 kinds spares parts. This enables Dowell to meets all requirements of its clients. Dowell has obtained multiples patents and international certificates.