In mundo industriali hodierno, quod celeriter mutat, certamen de conceptibus ad productos in mercato disponibiles est omnino altum. In casu firmarum quae praesunt in area innovationis in machinali, partibus automotive...

Vide Amplius

Prototypon industriale medium in mutatione paradigmatica est. Novus paradigmus appropinquat, quo tempora ducunt longa, impensaeque summae, et magna materiae damna solent characterizare processum. Nova directionis huius transformationis est usus impressoribus l...

Vide Amplius

Hic industria medica concurrit cum innovatione, praecisione, et necessitate, in sphera machinarum medicinalium. Conditiones intensae requirunt facultatem ad aperendum, personalizandum, et producendum instrumenta necessaria subito, et simpliciter veri...

Vide Amplius

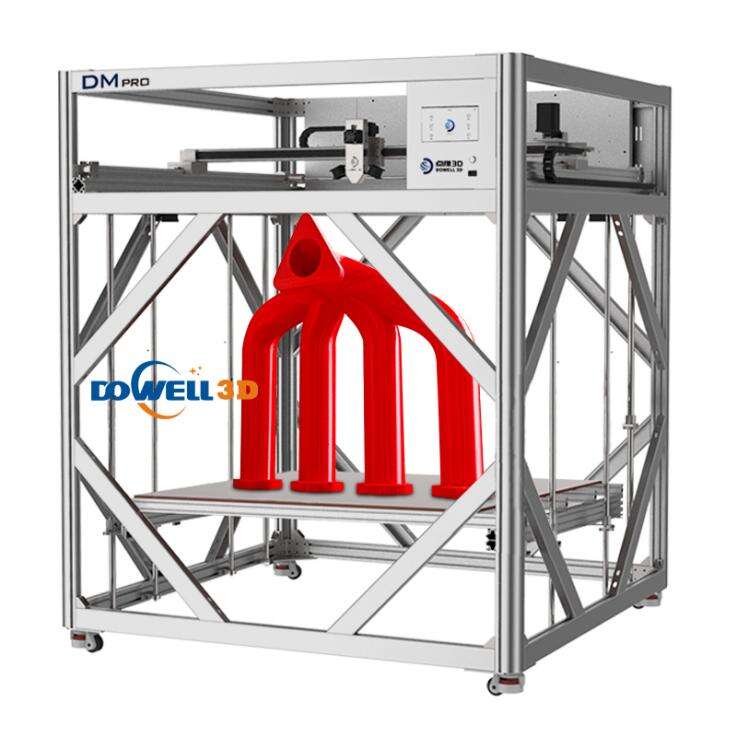

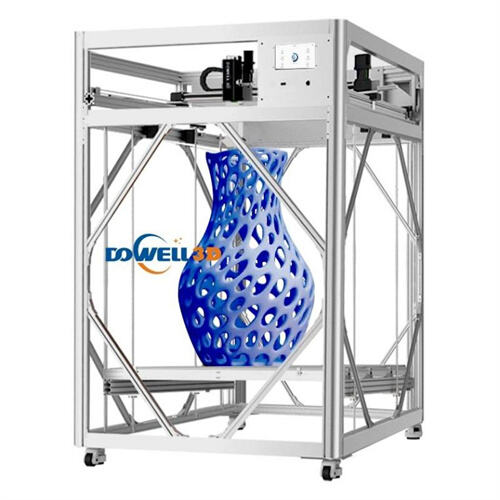

Fabricatio industrialis mutationem radicalem in aspectu suo experitur. Huius mutationis in centro, rapida adoptio technologiae impressionis 3D magnae scalae sita est. Principes industriales iam non ad parva composita cum prototypatione confin...

Vide Amplius

Huiusmodi progressio fabricationis additivae ex prototypatione ad productionem gradatim processit. Rolae imprimarum 3D maiorum in hoc processo mutantem magis importuna facta sunt. Ad quamcumque rem quaestuariam, quae cupit produc...

Vide Amplius

In mundo impressionis 3D industrialis, successus non solum debet definiri per impressum confectum esse. Sed verus experimentum est stabilis dimensio, accurate forma et magnitudo objecti impressi ab arte digitali usque ad opus consummatum servari...

Vide Amplius

Adoptatio industrialis technologiae impressionis 3D accelerat. Sed cum tanti producti hanc contentionem faciant, quid re vera est 'impressor 3D magni formati pro productione'? Respondeo: in quibusdam principiis fundamentalibus artis ingeniariae, quae in multis plus...

Vide Amplius

Fabricatio additiva campus semper evolvendus est, qui fines conceptionis et productionis amplificat. Impressores 3D tradicionales valde utiles sunt, sed impressores 3D magni formati orbem possibilitatum supplementarium praebent societatibus et artificibus. Hi...

Vide Amplius

Fabricatio additiva partium fortium et functionum iam amplius pervadit applicationes. Impressores 3D vulgares bene quidem sunt, sed homines quaerunt aliquid quod possit facere partes maiores multo maiori vi et ad...

Vide Amplius

Magnus quidam commutatio in prototypatione industriali est. Prototypa plena magnitudine evolvere olim processus erat lentus et sumptuosus, qui multas partes, conparationem complexam et instrumenta speciales per tot annos requirebat. Integratio novarum technologiarum in opere...

Vide Amplius

Vultus productionis industrialis vehementer mutatur. Cum industriae efficietiores sint cum tempore ad mercatum pleno et partibus geometriisque semper magis complexis introducendis, limites processuum vulgarium apparent. In hoc casu...

Vide Amplius

Magna magnitudo impressionis 3D velut area luderorum est ad manufacturam additivam, cum facultate imprimendi magnas partes functionales et prototypa. Quod ad voluminis incrementum attinet, nulla via facilis est, et studium ingeniariae longe diminutum est...

Vide Amplius