If you have ever dreamed of creating your own toys, jewelry, or even electronic gadgets, you will be happy to know that 3D printing allows you to bring your ideas to life. With the 3D printer machine or even Dowell 3D tpu printer filament, you can create three-dimensional objects layer by layer, using designs that you can either make yourself or download from the internet. We will talk about the advantages of using a 3D printer, the innovation behind it, how to use it safely, how to use it, its service quality, and its applications.

One of the biggest advantages of using a 3D printer of Dowell 3D is the ability to make anything that you can imagine. You can create prototypes, replacement parts, and even artistic pieces. This means that you can use the 3D printer for both personal and professional purposes.

Another advantage of the 3D printer is that it is a cost-effective way of creating models and prototypes. Instead of having to send off your designs to external manufacturers, you can produce them in-house, saving on production costs.

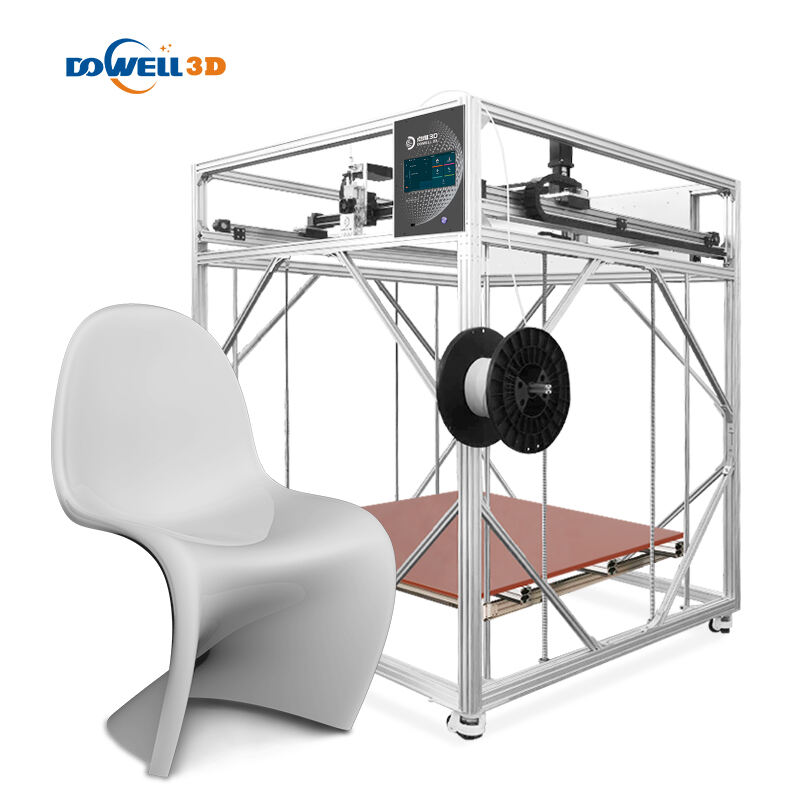

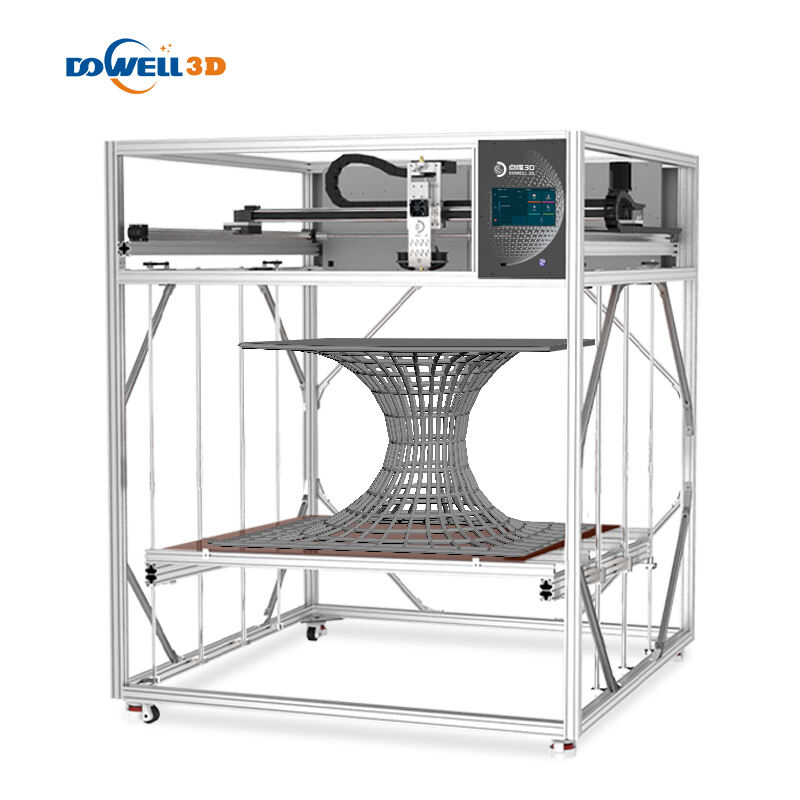

3D printing technology is a huge innovation in the world of manufacturing same with Dowell 3D large 3d printer. The process involves the creation of a physical object from a digital model, by laying down successive layers of material until the final product is complete. This is an innovative process because it allows anyone to create their own designs and bring them to life.

It is important to be aware of the safety measures that come with using a 3D printer made by Dowell 3D . Always ensure that the machine is located in a well-ventilated area, as fumes can be emitted during the printing process. Additionally, be sure to wear protective gloves and safety goggles when handling the printer's materials. Finally, ensure that the machine is properly calibrated and that there is no risk of fire.

Using the 3D printer is a relatively simple process. First, you need to create the design that you want to print using a computer-aided design (CAD) software. Once you have your design, you can either print it directly or send it to the 3D printer software like for Dowell 3D carbon fiber 3d printer. The software will then convert the design into a series of instructions for the printer, which will then proceed to create the object layer by layer.

Dowell's 3 d printer machine and manufacturing facility six series and more than 100 distinct models products, and 300 types of spares parts. This allows Dowell meet all the requirements of it clients. Dowell has been awarded multiples international certifications and patents.

Dowell's principal customers are research institutes, universities and 3 d printer machine. They serves more 20,000 customers around the globe and exports to more than 60 countries. They provides the most reliable and secured logistics ensure that each products will reach every client completely and efficiently.

The company's main business 3 d printer machine and 3D materials. Our primary products FDM plastics filament printers as well as FGF plastic particles 3D printers. 3D materials includes PLA, PETG ABS, TPU, Glass Fiber, Carbon Fiber, PP, and other composites materials.

The business is protected under intellectual property rights and has been awarded independent certificates from SGS, FCC, CE and many more. It has 3 d printer machine. Before leaving the factory, every product is tested thoroughly and a report is issued.

When considering the service quality of the Dowell 3D who manufactured 3D printer machine, it is important to consider the precision and accuracy of the printed output. The quality of the printed object will depend on the printer's resolution, or the thickness of each layer that it prints. It is important to choose a high-resolution printer if you want to create detailed designs.

The applications of the 3D printer are endless same with Dowell 3D multi color 3d printer. It can be used to create replacement parts for broken machinery, or even custom prosthetic limbs. It can also be used for household items such as phone cases, lamps, and even kitchenware. In the field of medicine, 3D printing is being used to create realistic anatomical models for training medical professionals.