What is CAD for 3d printing?

What is CAD modeling? Compare 3D Printing Design Software.

Why is it an essential tool for digital manufacturing? Explore the types of CAD software that can be used to bring ideas into the physical world through digital 3D modeling. Find the right software tool for your application.

What is CAD software?

CAD (Computer-Aided Design), also known as 3D modeling, allows engineers and designers to build realistic computer models of parts and assemblies for complex simulation and digital manufacturing. Models created with CAD can be produced as physical components through 3D printing, CNC machining, and injection molding.

Before any physical model is created, CAD software can simulate various parameters, including strength or temperature resistance. Using CAD software allows you to work faster and more cost-effectively without compromising the quality of the component.

What is solid modeling?

Solid modeling creates solid 3D models as if they were real parts, with a logical workflow similar to the processes used to manufacture parts. Some of these operations include extrusion, drilling, and tapping. Solid models can intersect, connect, and subtract objects from each other to create the desired part.

Another advantage of solid modeling is that it is often parametric, meaning that changes or parameters are saved at each stage of the modeling process and can be edited at any time. This allows the features of a model to be modified quickly without having to create the part from scratch.

Assembly modeling is an important stage in solid modeling, allowing individual parts to be assembled together to form complex models. Assemblies can be used to insert standard components downloaded directly from the manufacturer, such as fasteners or bearings. Motion elements can also be applied to assemblies, allowing the mechanical performance of the design to be evaluated using detailed motion analysis.

What is surface modeling?

Surface modeling is often used for the more aesthetic features of a product. It is easier to create more organic and free-form geometry using this type of CAD software. Many of the constraints in solid modeling are not a problem in surface modeling, however, this can sometimes reduce accuracy.

As the name implies, surface modeling only deals with the surface of a part, without the solid interior. However, once a part has enough surface to enclose the part, it can be filled and then used for 3D printing. When developing a design using surface modeling, it is difficult to go back and make changes because it is usually not parametric.

Each type of modeling software has advantages and disadvantages, depending on the type of design you want to make. Sometimes it's necessary to use both solid and surface modeling to combine the advantages of each.

What CAD programs do professionals use?

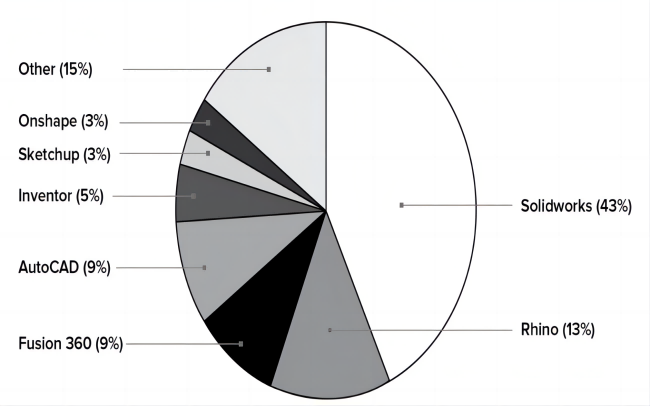

At the time of writing this article, we sent a survey to over 750 designers and engineers using the Protolabs network to find out which CAD software they prefer. Let's explore the results.

The survey found that most engineers and designers use Solidworks for CAD design. Engineers tend to choose AutoCAD, Inventor, and Fusion 360 (the only free professional CAD package on the list), while Rhino proved to be the second most popular modeling tool for designers. Interestingly, despite ranking highly among designers, Rhino did not appear on the list for engineers.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

BE

BE

HY

HY

KA

KA

LO

LO

LA

LA

MN

MN

NE

NE

SO

SO

MY

MY

KK

KK

UZ

UZ