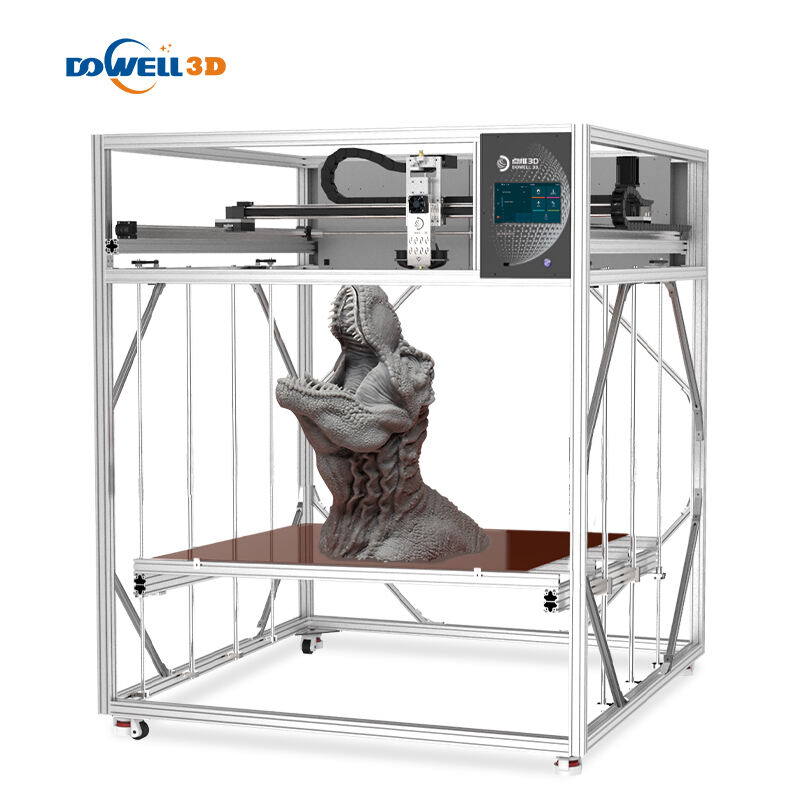

All About FDM 3D Printers: The Innovation that Sparks Fun and Creativity. Do you love creating stuff on your own? Do you want to turn your imagination into something real? Well, it's time to get yourself a FDM 3D printer. FDM stands for Fused Deposition Modeling, a 3D printing method that uses thermoplastic materials to create solid objects. Dowell 3D large print 3d printer are revolutionizing the world of DIY and manufacturing, especially with the advent of affordable and easy-to-use models.

The FDM 3D printer is a real game-changer when it comes to customization and creativity. Why? For one, you don't need any fancy design software to get started. You can use a Dowell 3D 3d printer parts or even download preexisting files from online libraries. Moreover, you can print out anything from simple objects like phone cases or toys, to complex items like machine parts or prosthetic limbs. Imagine being able to make your own guitar picks, key chains, or even furniture entirely from scratch.

FDM 3D printing is also driving innovation in several industries, like aerospace, architecture, medicine, and even food. With this revolutionary method, engineers and scientists can create prototypes and models that are faster, cheaper and more precise than with traditional methods. Dowell 3D aluminum 3d printer can also explore new geometries, shapes and functionalities that were not possible before, pushing the boundaries of what's possible in manufacturing and design.

If you are thinking of getting a FDM 3D printer for yourself or your child, safety should always be your top priority. A Dowell 3D 3d printed objects uses high-temperature materials that can cause burns or require proper ventilation in the working area. Therefore, it's essential to read the user manual carefully, follow the setup and maintenance instructions and wear protective gear if needed. It's also essential to supervise children when they're using the printer and teach them safe handling practices.

Using a Dowell 3D nylon 3d printing may seem daunting at first, but with a little bit of patience, you'll be amazed at what you can create. The basic steps of printing involve designing a model, loading it onto the printer's software, selecting print settings and materials, and then letting the printer do its magic. It's important to prepare the printing bed by leveling it and applying adhesive or masking tapes to ensure proper adhesion. After printing, you'll need to remove the support material and do some finishing touches to your object to make it smoother and more polished.

Dowell's Fdm 3d printer and manufacturing facility six series and more than 100 distinct models products, and 300 types of spares parts. This allows Dowell meet all the requirements of it clients. Dowell has been awarded multiples international certifications and patents.

Dowell's Fdm 3d printer, universities as well as technology-related companies. Dowell serves more s20,000 customers across globe, and exports to more 60 nations, offering security and reliability logistics to ensures that each items gets each customers fully and quickly.

The business is protected under intellectual property rights and has been awarded independent certificates from SGS, FCC, CE and many more. It has Fdm 3d printer. Before leaving the factory, every product is tested thoroughly and a report is issued.

The main activity of the business is FDM/FGF 3D printing and 3D materials. The current main products are FDM plastics filament 3D printers FGF 3D printers made of plastic particles, and Fdm 3d printer like ABS, PETG, PLA, TPU, Carbon fiber Glass fibers as well as PP and other composites materials.

Quality is another important aspect to consider when using FDM 3D printers. The quality of your prints will depend on several factors like the printing material, the printer's settings, and the design of the object. Some materials like PLA or ABS offer higher quality and durability, but they may be more difficult to work with. Alternatively, some printers may offer better resolution and accuracy, but they may come at a higher price point. In terms of applications, Dowell 3D 3d printer for car parts have a wide range of possibilities. From creating DIY projects at home to prototyping new products in the industry, FDM 3D printing is a versatile and powerful tool that allows for creativity and innovation. Some popular applications include creating cosplay props, jewelry, figurines, molds, architectural models, and even human organs.

Finally, when choosing a FDM 3D printer, it's important to consider the quality of service and support provided by the manufacturer or seller. Check if they offer technical assistance, warranties, replacement parts, or even online tutorials or forums where you can learn more about how to use your printer. Having a reliable customer service can make a big difference in your overall experience with a Dowell 3D carbon 3d printer.