Nylon 3D Printing - The Future of Innovation.

Introduction:

3D Printing has revolutionized the world of manufacturing, and with the advancement in technology, Dowell 3D nylon 3d printing has become one of the most innovative and reliable ways to produce high-quality prototypes and end-use products.

Nylon 3D Printing offers a plethora of benefits over traditional methods of manufacturing. Firstly, it eliminates the need for expensive tooling, which reduces the overall cost for producing parts. Secondly, Dowell 3D nylon filament enables the creation of complex geometries, ensuring the consistency and precision of each and every part. Lastly, Nylon 3D Printing allows for quick design changes, imperative for short production runs.

Nylon 3D Printing is always evolving and innovating with new materials coming onto the market to ensure it meets the needs of various industries. Dowell 3D nylon 3d printer filament has expanded to create different materials, each with its unique properties and characteristics. The possibilities are endless.

Nylon 3D Printing is a safe and eco-friendly way of manufacturing products. It produces little waste and reduces the carbon footprint. Dowell 3D carbon fiber nylon also ensures a high level of safety and quality control; the materials used in the printing process are non-toxic and durable. It is suitable for use in different industries, including the production of medical equipment, airplane parts, and car parts.

Nylon 3D Printing is versatile and can be used across various industries, including aerospace, automotive, medical, and fashion. Dowell 3D carbon nylon filament is suitable for creating gears, tools, prosthetics, orthotics, and complex designs.

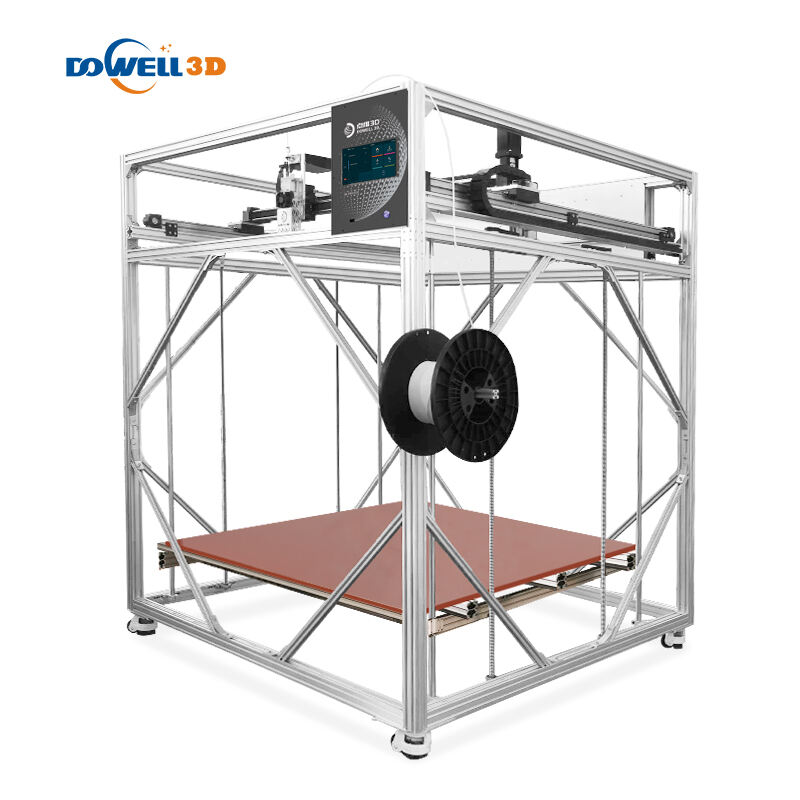

The main business of the firms is FDM/FGF printers, as well as 3D materials. Our most popular products includes FDM plastic filament printers as well as Nylon 3d printing 3D printers. 3D materials includes PLA, PETG ABS, TPU, Glass Fiber, Carbon Fiber, PP and many other composites materials.

Dowell's primary customers research institutes, universities as well as technology-related companies. More than 20,000 customers are serviced across the globe, and they Nylon 3d printing. They offer secures and reliable logistical services to ensures each product reaches it clients in total and full.

The business is protected under intellectual property rights and has been Nylon 3d printing from SGS, FCC, CE and many more. It is also designated as an Luoyang high-tech company. When the product leaves the factory, every product undergoes a rigorous test and a report issued.

Dowell has its owns manufacturing plants and R and D centers, with 6 series with more than 100 different models of products as well as Nylon 3d printing to fully satisfy the diverse needs of customers. Dowell has received numerous patents and internationals certifications.

Nylon 3D Printing is simple to use, and anyone can create high-quality prototypes or parts with just a 3D model and the right filament. One needs to install a Dowell 3D nylon filament and select the right filament. Once the model is designed, the machine will start printing the object layer by layer.

A high-quality Nylon 3D Printing service provider ensures that the entire process is seamless. The service provider must possess the required experience, skills, equipment, and technology to design and manufacture parts to exact specifications. Dowell 3D 3d printer for nylon also offer services such as prototyping, design consultation, post-processing, and finishing.

The quality of Nylon 3D Printing is outstanding, providing accuracy, precision, and consistency. Each and every printed part is durable and can withstand the wear and tear of everyday usage. Dowell 3D nylon 3d printer ensures short lead times and produces high-quality parts without breaking the bank.