What is FDM Printing and its Advantages?

FDM printing stands for Fused Deposition Modeling, which is a type of 3D printing technology, similar to the Dowell 3D's product like industrial metal 3d printer. FDM Printing Materials use a heated nozzle to melt and extrude plastic material, layer by layer, creating 3D objects. One of the main advantages of FDM printing is that it is a cost-effective technology that can produce complex geometries. FDM Printing Materials for a high level of customization, particularly when it comes to the size, shape, and color of a printed part. Another advantage of FDM printing is that it can produce very strong and durable parts that can withstand significant stress.

The innovation of FDM printing materials has been driven by the need to create high-quality parts that meet the demands of modern manufacturing processes, just like the home 3d printer from Dowell 3D. New materials are continuously being developed that can address specific application needs, such as flexibility, strength, and heat resistance. Some FDM printing materials can be used to create parts that have a similar texture and feel to human skin, making them ideal for medical applications. In recent years, FDM printing materials have also become more environmentally friendly, with many manufacturers creating bio-based filaments made from sustainable sources.

While FDM printing is considered to be a safe technology, there are some safety considerations to keep in mind, identical to Dowell 3D's product nylon carbon fiber 3d printer. Firstly, the melted plastic material used in FDM printing can be very hot, so it is important to handle it with care. some FDM printing materials can release harmful gases when heated, so it is important to use a well-ventilated area when printing. Finally, it is important to ensure that the 3D printer is set up and operated correctly to avoid any electrical hazards.

Using FDM printing materials is relatively straightforward, the same as 1000mm 3d printer made by Dowell 3D. Firstly, you need to have a 3D printer compatible with the material you wish to use. Once you have selected your material, you need to load it into the 3D printer and set the printer to the correct temperature and speed settings. You will also need to select the design for your part and import it into the printer's software. Once the design is loaded, you can preview the part and make any necessary adments before starting the printing process.

FDM Printing Materials it is important to work with a reputable 3D printing company that can provide the necessary expertise and equipment to produce your parts, identical to Dowell 3D's product abs filament 3d printer. A good service provider will be able to help you choose the right FDM printing material for your application, as well as provide guidance on how to optimize your design for quality and efficiency. Some common applications of FDM printing include creating prototypes, manufacturing parts for aerospace and automotive industries, and producing customized medical devices.

FDM printing materials offer many advantages in terms of cost-effectiveness, customization, durability, and environmental friendliness. The innovation of new materials and the development of better safety procedures have made FDM printing an increasingly popular choice for a wide range of applications. By following the proper procedures for using FDM printing materials, it is possible to produce high-quality parts that meet the needs of modern manufacturing processes.

Dowell's customers primarily research institutions, Fdm printing materials and businesses that are technology-based. More than 20,000 customers are serviced all over world, and they exports to over 60 nations. They provides secure and reliable logistical services ensures each products reaches its customer in full.

The company Fdm printing materials, SGS, FCC and other certifications. It has over 40 patents and is protected by independent intellectual property rights and is recognized as an "Luoyang High-tech Enterprises". Each products is rigorously tested before leaving the factory. a tests report is provided.

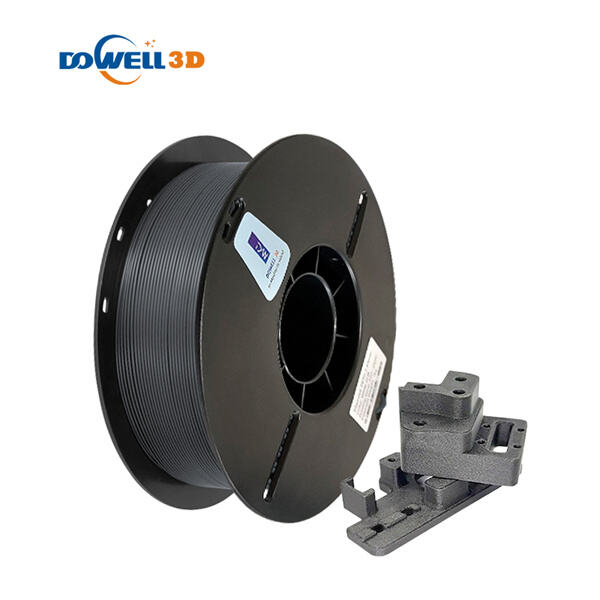

The Fdm printing materials is FDM/FGF printers as well 3D materials. Our most popular products includes FDM plastic filament printers as well as FGF plastics particle 3D Printers. 3D Materials includes PETG, PLA ABS, TPU and Glass Fiber, Carbon Fiber, PP and other composites materials.

Dowell's in-houses R and D and manufacturing centers houses six series products and Fdm printing materials, as well as 300 types of spares parts. This enables Dowell meets all requirements of it customers. Dowell received numerous internationals certifications and patents.