Nylon Carbon Fiber 3D Printer: A New Era in Creative Printing

Do you love to create things? Do you have a passion for designing unique objects? If yes, then you might be interested in the latest innovation in 3D printing – nylon carbon fiber 3D printer and also Dowell 3D nylon filament. It is a revolutionary machine that has the potential to take your creativity to the next level. This article will explain all the advantages, innovations, safety, uses, and services related to this amazing product.

Nylon carbon fiber 3D printer of Dowell 3D is a powerful tool that has numerous advantages. One of the most important advantages is its strength. This machine can produce objects that are much stronger than those made from ordinary materials. Carbon fiber reinforced nylon is one of the strongest materials available for 3D printing. Moreover, it is resistant to wear and tear, chemicals, and heat. Another advantage is its lightweight yet durable nature, which makes it an ideal choice for creating objects that need to be light and strong, such as drone parts and prosthetics.

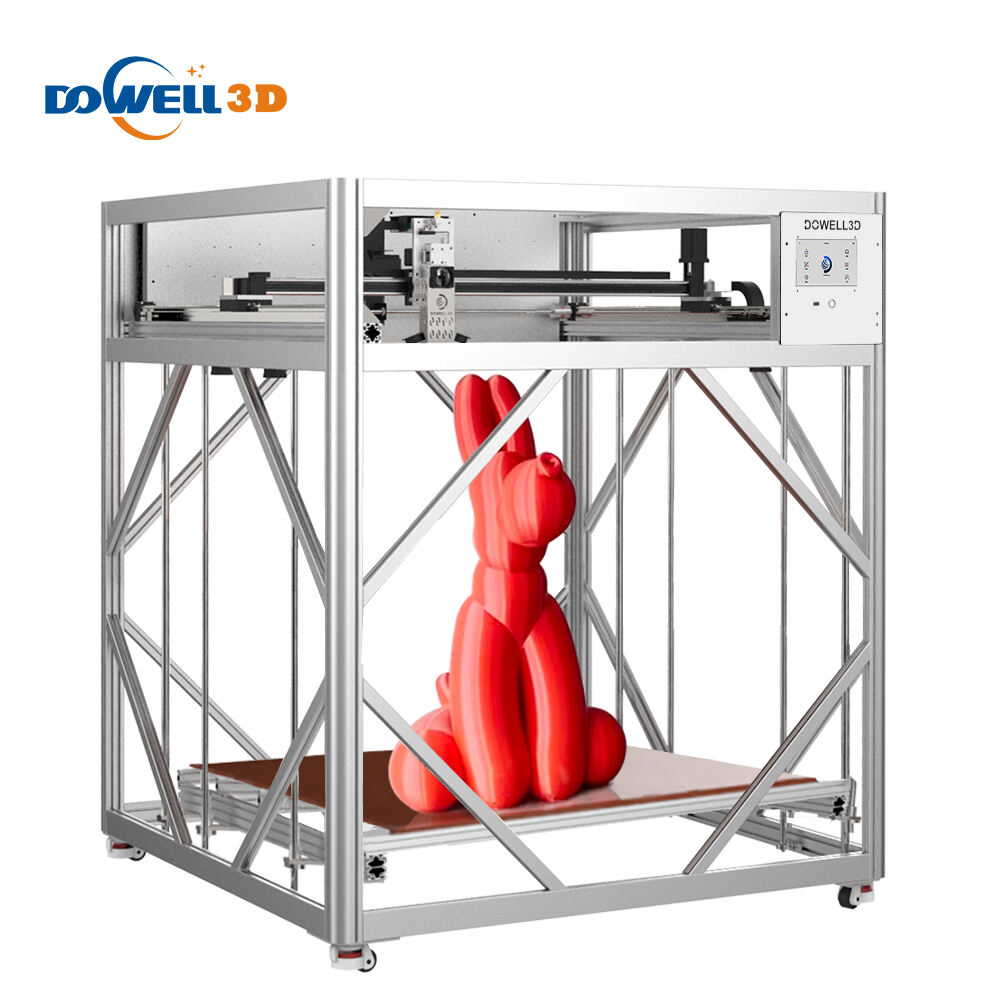

The nylon carbon fiber 3D printer or the Dowell 3D nylon 3d printing is the latest innovation in 3D printing technology. It is a machine that combines the strength of carbon fiber with the flexibility of nylon. This combination makes it a perfect choice for creating intricate and complex objects that were not possible with ordinary 3D printers. The innovation in this machine lies in its ability to print objects that are stronger, lighter, and more durable than those made from traditional materials. The use of advanced software and algorithms enables the machine to print with great accuracy and precision, making it an indispensable tool for designers, engineers, and artists.

Safety is a critical factor in any manufacturing process, and 3D printing is no exception. Dowell 3D Nylon carbon fiber 3D printer is designed with safety in mind. The use of carbon fiber and nylon materials reduces the emission of toxic fumes and particles, making it safe for the user and the environment. Moreover, the machine has built-in safety features that prevent accidents and injuries during the printing process. These safety features include automatic shut-off, heating and cooling systems, and emergency stop buttons.

Nylon carbon fiber 3D printer can be used for a variety of applications same with Dowell 3D carbon nylon filament, from creating toys and gadgets to producing industrial parts and tools. It can be used to make customized prosthetics and orthotics for patients with disabilities. It can also be used to print drone parts, car components, and aerospace parts. The machine's flexibility and precision make it an ideal choice for developing prototypes and testing new designs. With this machine, the possibilities are endless.

The company has passed CE, Nylon carbon fiber 3d printer, FCC and other certifications. It has more than 40 patents and is protected by intellectual property rights that are independent, and has been recognized as an "Luoyang High-Tech Enterprise". Before it leaves the factory each products is rigorously tested and a reports is prepared.

The principals activity of the firms Nylon carbon fiber 3d printer, as well as 3D materials. Our current products includes FDM plastics filament 3D printers, FGF 3D printers made plastic particles, and 3D materials, which includes PLA, PETG, ABS TPU, Carbon Fiber glass fiber, PP, and other composites materials.

Dowell's Nylon carbon fiber 3d printer and manufacturing centers houses six series products and more 100 different types of models products, as well as 300 types spares parts. This enables Dowell to meet requirements of its clients. Dowell has been awarded numerous internationals patents and certifications.

Dowell's Nylon carbon fiber 3d printer, universities as well as technology-related companies. Dowell serves more s20,000 customers across globe, and exports to more 60 nations, offering security and reliability logistics to ensures that each items gets each customers fully and quickly.

Using a nylon carbon fiber 3D printer from Dowell 3D is easy, even for beginners. First, choose the design you want to print from a computer-aided design (CAD) software and save it in a 3D printer file format. Then, load the carbon fiber nylon filament into the printer's extruder. The filament is heated, melted, and extruded through a nozzle to create the object layer by layer. During the printing process, the user can adjust the temperature, speed, and other settings to ensure the desired quality and finish. Once the printing is complete, the object can be removed from the printer and post-processed, such as sanding or painting, to get the desired look.

Buying a nylon carbon fiber 3D printer is an investment, and customers expect good service and quality from the manufacturer. When buying a 3D printer such as Dowell 3D nylon 3d printer, look for a reputable brand that offers good customer support, warranties, and maintenance services. It is important to ensure that the machine meets the industry's standards and regulations. Nylon carbon fiber 3D printer is a relatively new product, and customers should do their research before purchasing to avoid any surprises and disappointments.