What is Flexible TPU?

Flexible TPU stands for Thermoplastic Polyurethane, which is a type of plastic known for its elasticity high and. It is also resistant to oil, grease, and abrasion, making it a material ideal various application. Dowell 3D flexible tpu was a material innovative has become increasingly popular due to its many advantages.

Flexible TPU has advantages are many including its flexibility, durability, and strength. It is also resistant to oil, grease, and abrasion, making it a choice excellent industrial application. Additionally, it is easy and lightweight to handle, making it a favorite among manufacturers.

Another advantage of Dowell 3D tpu filament is its resistance to chemicals and UV rays, making it suitable for outdoor use. It is also resistant to water, making it a material ideal water-resistant product such as phone cases and watch straps.

In recent years, there has been a complete lot of innovation in Dowell 3D tpu 3d printing. Manufacturers are experimenting with different blends of TPU to create materials are even more flexible, durable, and resistant to factors are external.

Moreover, advances in 3D printing technology have made it easier to create shapes are complex designs using flexible TPU. This has led to the creation of unique products such as custom phone cases and shoe flexible.

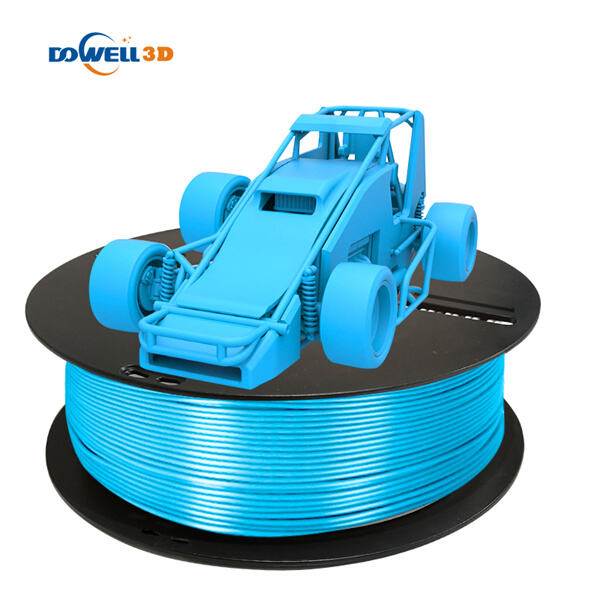

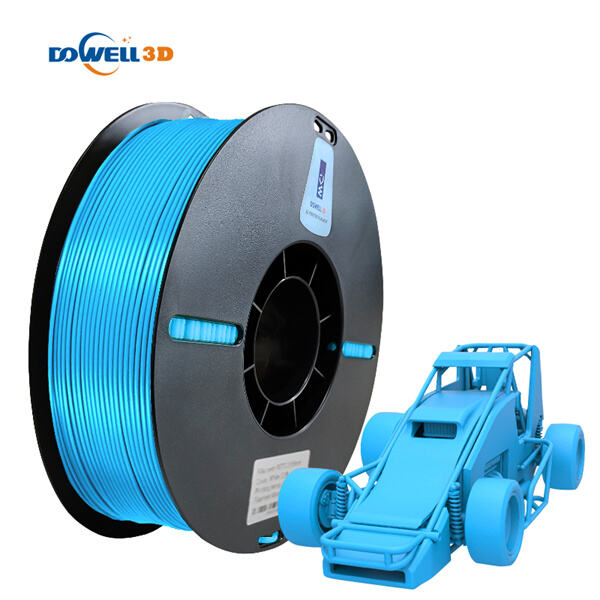

Flexible TPU can be used in a variety of ways, including injection molding, 3D printing, and extrusion. Dowell 3D tpu 3d filament can be used to create products such as phone cases, watch straps, shoe soles, and more. Additionally, it is used in the automotive and electronic companies to generate durable, flexible parts.

When using flexible TPU, it is important to follow the manufacturer's instructions and use the equipment appropriate. Flexible TPU can be melted and molded into different shapes, making it a material versatile a variety of applications.

When purchasing TPU flexible is important to ensure that you are getting a quality product. Look for reputable manufacturers and suppliers who offer high-quality materials and customer service excellent.

Quality is important when using flexible TPU, as it affects the durability and performance regarding the product finished. In addition to quality materials, it is also essential to use safety appropriate when working with Dowell 3D tpu printer filament.

Dowell a manufacturing workshops and Flexible tpu, with six series includes more than 100 models products and more than 300 types spares parts to fully meets various requirements of its customers. Dowell has received numerous internationals certificates and patents.

The business is protected under intellectual property rights and has been awarded independent certificates from SGS, FCC, CE and many more. It has Flexible tpu. Before leaving the factory, every product is tested thoroughly and a report is issued.

The main business of the firms FDM/FGF printers, as well as Flexible tpu. Our main products includes FDM plastic filament printers and FGF plastic particles 3D Printers. 3D Materials include PLA, PETG ABS, TPU and Glass Fiber, Carbon Fiber, PP, and other composites materials.

Dowell's clients mostly universities, research institutions and businesses that are technology-based. More than Flexible tpu, and they exports products to more than 60 nations. They offers safe and reliable logistics in orders ensure that every products gets to its purchaser in complete and in full.