Introduction

3D printing has revolutionized way we think about creating objects. With its ability to actually produce objects of almost any shape and size, 3D printing quickly become popular way to bring ideas to life. Here are some information can help you better understand 3d printing material from Dowell 3D and how it can benefit you.

There are many advantages to 3D printing. Firstly, it allows for customized designs, means you can create a tailor-made product to fit your needs. Second, 3D printing truly is certainly fast and efficient, allowing for quicker turnaround time than traditional manufacturing processes. Third, Dowell 3D 3d materials really versatile, meaning it can be used to create wide array of objects, from toys to medical equipment.

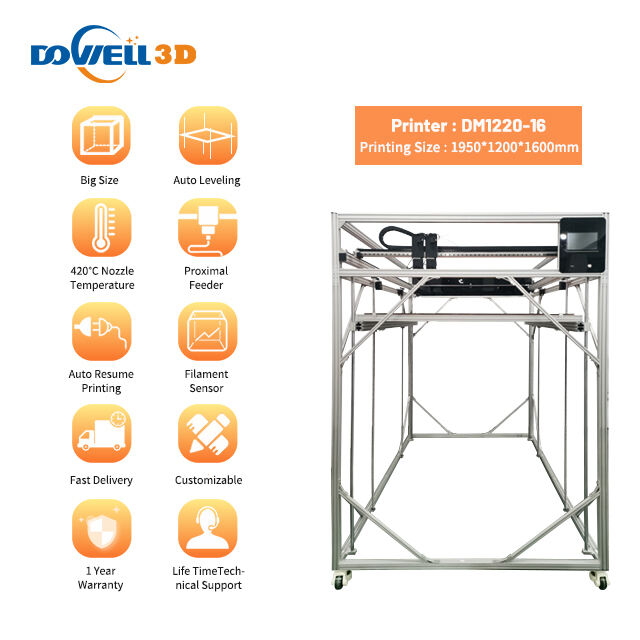

Innovation is at the heart of 3D printing technology. With new materials constantly being developed, there is no shortage of possibilities when it comes to designing and creating objects. Advances in software have also made it easier than ever to design and print 3D objects, making the Dowell 3D multi material 3d printer more accessible to wider range of people.

Safety is top priority when using any tool or technology, and 3D printing is no exception. It is important to follow Dowell 3D's instructions when using 3D printer, and to always wear protective equipment when necessary. Proper ventilation is also important when using certain 3d print soft material, as they can produce fumes that may be harmful if inhaled.

Using 3D printer can seem intimidating at first, but it is actually quite simple. First, you will need to have a design in mind. This can be created using 3D design software, or you can find pre-made designs online. Once you have your design, you will need to prepare Dowell 3D printer by loading it with appropriate material. Finally, you can send design to large 3d printer and wait for it to finish printing your object.

The business is protected under intellectual property rights. The 3d materials from SGS, FCC, CE and many others. The company is also identified as an Luoyang high-tech enterprise. Each product is thoroughly tested before leaving the factory. an evaluation report is issued.

Dowell's in-houses R and D and manufacturing centers houses six series products and 3d materials, as well as 300 types of spares parts. This enables Dowell meets all requirements of it customers. Dowell received numerous internationals certifications and patents.

Dowell's customers includes mainly research institutes, universities as well as 3d materials. Dowell serves more 20,000 customers around the world and exports their products over 60 countries. They offers security and reliability in logistics to ensures each products gets to each customer fully and quickly.

The company's main business 3d materials and 3D materials. Our primary products FDM plastics filament printers as well as FGF plastic particles 3D printers. 3D materials includes PLA, PETG ABS, TPU, Glass Fiber, Carbon Fiber, PP, and other composites materials.

The quality of a 3D printed object can vary depending on a number of factors, including the type of material used and the design of object. However, with careful selection of Dowell 3D materials and precise printing parameters, it is possible to create high-quality objects both durable and aesthetically pleasing.

3D printing technology has wide range of applications, from creating prosthetic limbs to designing custom jewelry. It is also being used in aerospace and automotive industries to create lightweight and intricately designed parts. With so many possibilities, applications of Dowell 3D printing technology are virtually limitless.