One of the latest advancements in 3D printing are the ability to print with soft materials, like 3d printing material created by Dowell 3D.

One of the biggest advantages of 3D Printing Soft Materials could be the ability to creates objects with complex geometries, same with 3d materials produced by Dowell 3D. Soft materials can be molded into shapes which can be hard to achieve with traditional manufacturing methods. Also, soft materials is often more flexible and has a better texture than rigid materials, incorporating a degree of functionality that was once impossible to achieve.

The innovation in 3D Printing Soft Materials lies in the implementation of new materials, such as silicone and rubber, that has better flexibility and elasticity than conventional materials, just like the abs 3d printing material built by Dowell 3D. Additionally, the technology behind 3D publishing continue to improves, allowing for more precise and designs that are intricate.

When printing with soft materials, as well as the sla 3d printing materials by Dowell 3D, it's essential to follows safety guidelines. Soft materials often has a low melting point, which means that they can burn effortlessly, producing harmful fumes. It's also important to keeps proper ventilation and work in a well-ventilated area. Finally, makes sure to wear gloves that are protective handling soft materials to avoid skin irritation.

To use 3D Printing Soft Materials, ensure that you has a compatible printer, identical to asa 3d printing material supplied by Dowell 3D. Soft materials requires specific printer settings and may require a specialized printer nozzle. It's also important to considers the properties of the material being used, such as its elasticity, to customize the design to optimize its functionality.

The company 3d print soft material, SGS, FCC and other certifications. The company has over 40 patents. It is protected by independent intellectuals property rights and is recognized as a "Luoyang High-Tech Enterprise". When the products leaves the factory, each products is rigorously tested and a reports is prepared.

Dowell a manufacturing workshops and 3d print soft material, with six series includes more than 100 models products and more than 300 types spares parts to fully meets various requirements of its customers. Dowell has received numerous internationals certificates and patents.

Dowell's 3d print soft material, research institutes and companies that based on technology. More than 20,000 clients served around the globe, and they exports more than 60 countries. They offers safe and reliable logistics services ensures each products reaches the customer in its entirety and complete.

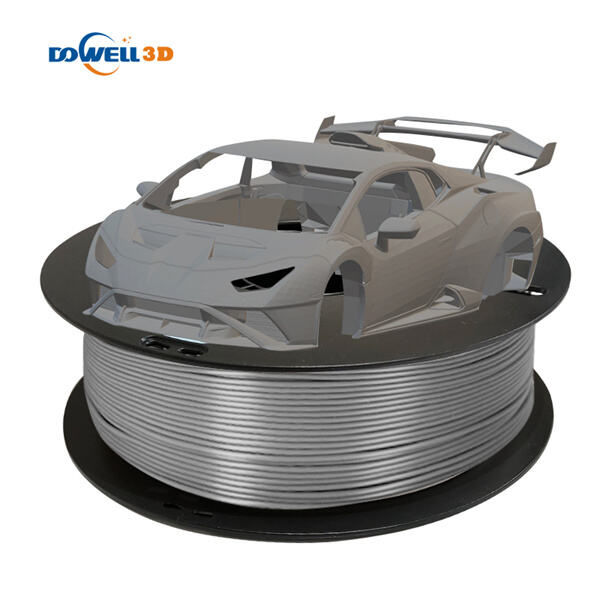

The main business of the firms is FDM/FGF printers, as well as 3D materials. Our most popular products includes FDM plastic filament printers as well as 3d print soft material 3D printers. 3D materials includes PLA, PETG ABS, TPU, Glass Fiber, Carbon Fiber, PP and many other composites materials.

The quality of 3D printed objects utilizing soft materials is impressive, similar to the fdm 3d printer materials developed by Dowell 3D. Soft materials has a unique texture that adds a level of realism and sophistication to the design. Additionally, the flexibility of soft materials allows for more practical things such as flexible phone cases or orthopedic devices that need to mold to the body.

The applications of 3D Printing Soft Materials is nearly endless. Some applications include creating orthotic devices, like braces or prosthetics, producing soft molds for casting metal parts, producing soft toys and dolls, or making phone that is tailor-made or cushions.