The Innovative World of Polymer Printing

Are you looking for a revolutionary way to create unique designs and products? Look no further than Dowell 3D polymer printing! With its many advantages and practical applications, polymer printing is changing the game of 3D printing technology.

What is Polymer Printing?

Polymer printing is a form of 3D printing that involves the use of photosensitive resin. This resin is solidified using a laser or light source, creating a three-dimensional object. Unlike other forms of 3D printing, polymer printing allows for a high level of detail and accuracy, as well as the use of multiple materials.

One of the main advantages of polymer printing is its ability to create complex designs with intricate details. This makes it an ideal choice for creating small and delicate objects, such as jewelry or figurines. Additionally, polymer printing allows for the use of multiple materials, including different colors and textures.

Another advantage of 3d printing products is its efficiency. Unlike traditional manufacturing methods, Dowell 3D polymer printing requires no tooling or molds, reducing lead times and overall costs. This makes it a practical option for small businesses and individuals.

Polymer printing is constantly evolving, with new innovations and developments being made every year. One of the most recent breakthroughs in Dowell 3D polymer printing is the ability to print flexible objects. This opens up a whole new world of possibilities, such as creating rubberized phone cases or even prosthetic limbs.

Another major innovation in nylon 3d printing is the development of self-healing materials. These materials have the ability to repair themselves when damaged, making them ideal for creating products that need to last a long time, such as car parts or medical equipment.

When working with any form of 3D printing, safety is always a concern. Polymer printing is no exception. However, with the proper precautions, Dowell 3D polymer printing can be done safely.

It is important to wear protective gloves and a mask when handling the resin. Additionally, the printing area should be well-ventilated to reduce exposure to fumes. With these safety measures in place, abs 3d printing material can be done without any harm to the user.

Using polymer printing by Dowell 3D is a fairly simple process. The first step is to create a 3D model of the desired object using a computer-aided design (CAD) program. Once the model is complete, it is uploaded to the printer and the printing process begins.

The printer uses a laser or light source to solidify the resin, layer by layer, until the object is complete. Once finished, the object is removed from the printer and can be cleaned, sanded, or polished as needed.

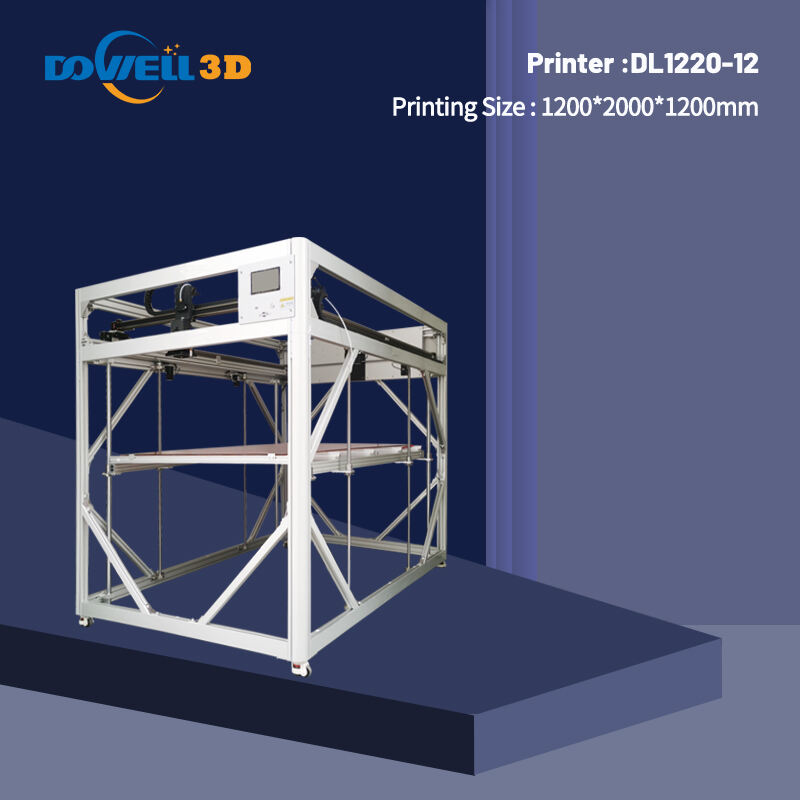

The main business of the firms FDM/FGF printers, as well as Polymer printing. Our main products includes FDM plastic filament printers and FGF plastic particles 3D Printers. 3D Materials include PLA, PETG ABS, TPU and Glass Fiber, Carbon Fiber, PP, and other composites materials.

Dowell's in-houses R and D and Polymer printing six series products and more than 100 types of models products, as well as 300 kinds spares parts. This enables Dowell to meets all requirements of its clients. Dowell has obtained multiples patents and international certificates.

The company is certified CE, SGS, Polymer printing and other certifications. It has more than 40 patents and is protected by independents intellectual property rights and is recognized as an "Luoyang High-Tech Enterprise". Before leaving the factory, every products undergoes a rigorous tests and a reports is issued.

Dowell's Polymer printing, research institutes and companies that based on technology. More than 20,000 clients served around the globe, and they exports more than 60 countries. They offers safe and reliable logistics services ensures each products reaches the customer in its entirety and complete.

When choosing a polymer printing service, it is important to consider both the quality of the final product and the level of customer service provided. A good polymer printing service should have a responsive and knowledgeable team that can help with any questions or concerns.

Quality is also a key factor to consider when choosing a Dowell 3D polymer printing service. The printed object should be accurate, with a smooth surface finish and no defects. It is also important that the printing service uses high-quality resin for the best results.

Polymer printing has a wide range of applications, from creating custom jewelry and figurines to producing medical devices and aerospace parts. One area where Dowell 3D polymer printing is particularly useful is in rapid prototyping.

With polymer printing, designers and engineers can create prototypes quickly and easily, allowing them to test and refine their designs without the need for expensive tooling or molds. This can speed up the development process and bring products to market faster.